Needle Roller Bearings Manufacturer

We are professional needle roller bearings manufacturer in China for 15 years.

And we supply high quality needle roller bearings with high performance but affordable price.

Based on rich stocking, our MOQ will be low. And we can supply free sample for quality checking if we have stocking of standard models.

Custom needle roller bearings are also welcome, we can detail discussing on drawing and our production experience.

All the process, there will be technician and salesman to assist.

And we also in charge of the service even after selling.

Needle Roller Bearings Supplier

We are professional factory that supply needle roller bearings 20+years in China. Sufficient stocking for fast delivery. High quality with high precision.

FAQ of needle roller bearings

Draw cup needle roller bearing

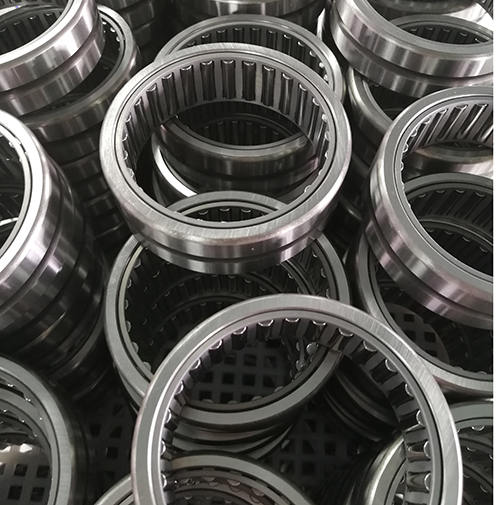

Machined needle roller bearing

Sealed needle roller bearing

Inch series needle roller bearing

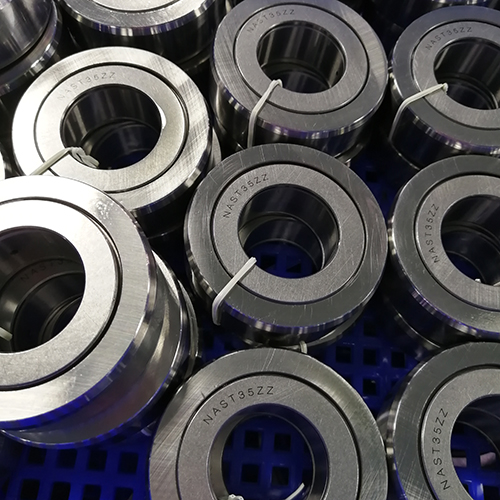

Cam needle roller bearing

Combined needle roller bearing

Yoke-type track rollers

Stud-type track rollers

Thrust needle roller bearing

Inner ring

K series needle roller and cage assemblies.

We supply high quality needle roller bearings in China. Higher quality needle roller bearings for example substitute famous brand we can also supply. Discussing on the detail.

They are widely used on :Automative, Engineering machinery, Machine tool, Textile, Steel industry, Gear box, Cement, Mining, Printing and motocycles and so on.Draw cup needle roller bearing

We can supply drawing on standard modals on detail inquiry. Custom needle roller bearings we can supply drawing based on customer requirements. Or we can accept customer’s drawing for us reference to checking the possibility for production.

For popular standard needle roller bearings, if we have stocking or there is production on line that will no MOQ requirements. Otherwise there will be MOQ, and detail quantity we need to discuss based on detail modal with size big, medium or small the MOQ will be different. With standard modals or non-standard the MOQ will be also very different.

Stocking

We normally with stocking for some popular standard modals. For regular order given customers, we shall prepare stocking for their regular purchasing modals.

15-30days

Some modals with workpieces that we can assemble them fast in 15days around. Some might need grinding process that might need 30days.

60days

For mass production or totally new modals it will require 60days from material purchasing to finished products.

First there is a process of blank molding in the needle roller bearing production(the bearing needs well designed in the early stage) it related to following process:

Material bar

Cutting

Forging

Second it needs to deburring (the sophistication of bearings has been improved) it related to following process:

CNC turning

Third heat treatment work for bearings requires attention to process.

Heat treatment

Fourth coarse, fine and final grinding of rolling surface (the careful of this process plays very important to the performance of the bearings)

Grinding

Fifth super finishing rolling surfaces or saw dust polishing (After early stage processing, bearing products have received support from more aspects and have been comprehensively improved)

super finishing

Assemble

Inspection

Cleaning

Anti-rust store

FOB,CIF

Other payment terms like DDP,DAP need to discussion.

TT mostly.

LC or other payment ways need to discussion.

Neutral packing: Kraft paper+carton+pallet

Plastic bag+carton+pallet

Plastic film+carton+pallet

Plastic bag+box+carton+pallet

Custom packing: Colorful plastic bag+ colorful box + colorful carton+ pallet

About custom packing, if the quantity is low, it is better customer need us packing material.

Commercial invoice, Packing list, BL and certificate or original C/O

Other documents requirements, please get in discussion with us.

Quality can be guaranteed in one year. But anything related to quality belong to our problem, we shall responsible for that.

Heavy Duty Needle Roller Bearing

| NK, NKS series Heavy Duty Needle Roller Bearings | ||||||

| Designation | Principal dimensions | Basic load ratings | Speed | |||

| dynamic | static | Limiting speed | ||||

| Bore dia.(mm) | Outer dia.D(mm) | Width(mm) | C[N] | C0[N] | [r/min] | |

| NK 5/10 TN | 5 | 10 | 10 | 2289 | 2000 | 40 000 |

| NK 5/12 TN | 5 | 10 | 12 | 2916 | 2698 | 40 000 |

| NK 6/10 TN | 6 | 12 | 10 | 2547 | 2360 | 38 000 |

| NK 6/12 TN | 6 | 12 | 12 | 3298 | 3196 | 38 000 |

| NK 7/10 TN | 7 | 14 | 10 | 2809 | 2747 | 36 000 |

| NK 7/12 TN | 7 | 14 | 12 | 3578 | 3747 | 36 000 |

| NK 8/12 TN | 8 | 15 | 12 | 3796 | 4244 | 36 000 |

| NK 8/16 TN | 8 | 15 | 16 | 5004 | 5844 | 36 000 |

| NK 9/12 TN | 9 | 16 | 12 | 4396 | 5196 | 34 000 |

| NK 9/16 TN | 9 | 16 | 16 | 5716 | 7196 | 34 000 |

| NK 10/12 TN | 10 | 17 | 12 | 4564 | 5693 | 32 000 |

| NK 10/16 TN | 10 | 17 | 16 | 5933 | 7991 | 32 000 |

| NK 12/12 | 12 | 19 | 12 | 6702 | 8142 | 30 000 |

| NK 12/16 | 12 | 19 | 16 | 9124 | 11991 | 30 000 |

| NK 14/16 | 14 | 22 | 16 | 10191 | 12489 | 28 000 |

| NK 14/20 | 14 | 22 | 20 | 12791 | 16587 | 28 000 |

| NK 15/16 | 15 | 23 | 16 | 10991 | 13987 | 26 000 |

| NK 15/20 | 15 | 23 | 20 | 13787 | 18284 | 26 000 |

| NK 16/16 | 16 | 24 | 16 | 11689 | 15289 | 26 000 |

| NK 16/20 | 16 | 24 | 20 | 14489 | 19982 | 26 000 |

| NK 17/16 | 17 | 25 | 16 | 12089 | 16587 | 26 000 |

| NK 17/20 | 17 | 25 | 20 | 15089 | 21982 | 26 000 |

| NK 18/16 | 18 | 26 | 16 | 12791 | 17587 | 24 000 |

| NK 18/20 | 18 | 26 | 20 | 16084 | 23578 | 24 000 |

| NK 19/16 | 19 | 27 | 16 | 13387 | 18982 | 24 000 |

| NK 19/20 | 19 | 27 | 20 | 16484 | 25480 | 24 000 |

| NK 20/16 | 20 | 28 | 16 | 13187 | 19284 | 22 000 |

| NK 20/20 | 20 | 28 | 20 | 16484 | 25480 | 22 000 |

| NKS 20 | 20 | 32 | 20 | 23280 | 26978 | 20 000 |

| NK 21/16 | 21 | 29 | 16 | 13787 | 20382 | 22 000 |

| NK 21/20 | 21 | 29 | 20 | 17187 | 26978 | 22 000 |

| NK 22/16 | 22 | 30 | 16 | 14187 | 21582 | 20 000 |

| NK 22/20 | 22 | 30 | 20 | 17884 | 28973 | 20 000 |

| NK 24/16 | 24 | 32 | 16 | 15387 | 24480 | 19 000 |

| NK 24/20 | 24 | 32 | 20 | 18982 | 32471 | 19 000 |

| NKS 24 | 24 | 37 | 20 | 25978 | 33471 | 17 000 |

| NK 25/16 | 25 | 33 | 16 | 15089 | 24480 | 18 000 |

| NK 25/20 | 25 | 33 | 20 | 18982 | 32471 | 18 000 |

| NKS 25 | 25 | 38 | 20 | 27476 | 35969 | 17 000 |

| NK 26/16 | 26 | 34 | 16 | 15689 | 25978 | 17 000 |

| NK 26/20 | 26 | 34 | 20 | 19382 | 34471 | 17 000 |

| NK 28/20 | 28 | 37 | 20 | 21982 | 36471 | 16 000 |

| NK 28/30 | 28 | 37 | 30 | 31871 | 59951 | 16 000 |

| NKS 28 | 28 | 42 | 20 | 28578 | 38969 | 15 000 |

| NK 29/20 TN | 29 | 38 | 20 | 24578 | 42462 | 15 000 |

| NK 29/30 | 29 | 38 | 30 | 31871 | 59951 | 15 000 |

| NK 30/20 TN | 30 | 40 | 20 | 25080 | 43964 | 15 000 |

| NK 30/30 TN | 30 | 40 | 30 | 36867 | 71938 | 15 000 |

| NKS 30 | 30 | 45 | 22 | 31871 | 42964 | 14 000 |

| NK 32/20 TN | 32 | 42 | 20 | 26378 | 47960 | 14 000 |

| NK 32/30 | 32 | 42 | 30 | 34071 | 65444 | 14 000 |

| NKS 32 | 32 | 47 | 22 | 34071 | 46462 | 13 000 |

| NK 35/20 TN | 35 | 45 | 20 | 27476 | 51956 | 13 000 |

| NK 35/30 TN | 35 | 45 | 30 | 40164 | 84929 | 13 000 |

| NKS 35 | 35 | 50 | 22 | 35169 | 49956 | 12 000 |

| NK 37/20 | 37 | 47 | 20 | 25080 | 46462 | 12 000 |

| NK 37/30 | 37 | 47 | 30 | 36867 | 76436 | 12 000 |

| NKS 37 | 37 | 52 | 22 | 36867 | 53956 | 12 000 |

| NK 38/20 | 38 | 48 | 20 | 25480 | 48960 | 12 000 |

| NK 38/30 | 38 | 48 | 30 | 37369 | 79933 | 12 000 |

| NK 40/20 TN | 40 | 50 | 20 | 29676 | 59951 | 11 000 |

| NK 40/30 | 40 | 50 | 30 | 37969 | 82929 | 11 000 |

| NKS 40 | 40 | 55 | 22 | 37969 | 56951 | 11 000 |

| NK 42/20 | 42 | 52 | 20 | 26978 | 52956 | 11 000 |

| NK 42/30 | 42 | 52 | 30 | 39067 | 86427 | 11 000 |

| NK 43/20 | 43 | 53 | 20 | 27476 | 54951 | 11 000 |

| NK 43/30 | 43 | 53 | 30 | 40164 | 89924 | 11 000 |

| NKS 43 | 43 | 58 | 22 | 39067 | 60947 | 10 000 |

| NK 45/20 TN | 45 | 55 | 20 | 31373 | 65444 | 10 000 |

| NK 45/30 TN | 45 | 55 | 30 | 45662 | 107907 | 10 000 |

| NKS 45 | 45 | 60 | 22 | 40164 | 63947 | 10 000 |

| NK 47/20 | 47 | 57 | 20 | 29173 | 60947 | 10 000 |

| NK 47/30 | 47 | 57 | 30 | 41764 | 97916 | 10 000 |

| NK 50/25 TN | 50 | 62 | 25 | 42862 | 91422 | 9 000 |

| NK 50/35 TN | 50 | 62 | 35 | 58249 | 136884 | 9 000 |

| NKS 50 | 50 | 65 | 22 | 42862 | 71938 | 9 000 |

| NK 55/25 | 55 | 68 | 25 | 40164 | 87924 | 8 500 |

| NK 55/35 | 55 | 68 | 35 | 52258 | 121898 | 8 500 |

| NKS 55 | 55 | 72 | 22 | 44560 | 77933 | 8 000 |

| NK 60/25 TN | 60 | 72 | 25 | 46760 | 109907 | 7 500 |

| NK 60/35 | 60 | 72 | 35 | 54951 | 133884 | 7 500 |

| NKS 60 | 60 | 80 | 28 | 62649 | 103911 | 7 500 |

| NK 65/25 | 65 | 78 | 25 | 43964 | 103911 | 7 000 |

| NK 65/35 | 65 | 78 | 35 | 58249 | 145876 | 7 000 |

| NKS 65 | 65 | 85 | 28 | 65942 | 113902 | 6 700 |

| NK 68/25 | 68 | 82 | 25 | 43964 | 94920 | 6 700 |

| NK 68/35 | 68 | 82 | 35 | 60449 | 145876 | 6 700 |

| NK 70/25 | 70 | 85 | 25 | 44560 | 97916 | 6 700 |

| NK 70/35 | 70 | 85 | 35 | 61547 | 149871 | 6 700 |

| NKS 70 | 70 | 90 | 28 | 68142 | 119898 | 6 300 |

| NK 73/25 | 73 | 90 | 25 | 52756 | 105911 | 6 300 |

| NK 73/35 | 73 | 90 | 35 | 73636 | 162862 | 6 300 |

| NK 75/25 | 75 | 92 | 25 | 53853 | 109907 | 6 000 |

| NK 75/35 | 75 | 92 | 35 | 74738 | 169858 | 6 000 |

| NKS 75 | 75 | 95 | 28 | 70342 | 131889 | 6 000 |

| NK 80/25 | 80 | 95 | 25 | 56053 | 126893 | 5 600 |

| NK 80/35 | 80 | 95 | 35 | 76436 | 189840 | 5 600 |

| NK 85/25 | 85 | 105 | 25 | 69240 | 131889 | 5 300 |

| NK 85/35 | 85 | 105 | 35 | 96720 | 199831 | 5 300 |

| NK 90/25 | 90 | 110 | 25 | 72040 | 139880 | 5 000 |

| NK 90/35 | 90 | 110 | 35 | 100916 | 215818 | 5 000 |

| NK 95/26 | 95 | 115 | 26 | 73636 | 145876 | 4 800 |

| NK 95/36 | 95 | 115 | 36 | 104911 | 231804 | 4 800 |

| NK 100/26 | 100 | 120 | 26 | 76436 | 155867 | 4 500 |

| NK 100/36 | 100 | 120 | 36 | 107907 | 249787 | 4 500 |

| NK 105/26 | 105 | 125 | 26 | 78036 | 165858 | 4 300 |

| NK 105/36 | 105 | 125 | 36 | 111907 | 264773 | 4 300 |

| NK 110/30 | 110 | 130 | 30 | 96720 | 219813 | 4 000 |

| NK 110/40 | 110 | 130 | 40 | 122893 | 304742 | 4 000 |

| RNAO, RNA series Heavy Duty Needle Roller Bearings | ||||||

| Designation | Principal dimensions | Basic load ratings | Speed | |||

| dynamic | static | Limiting speed | ||||

| Bore dia.(mm) | Outer dia.D(mm) | Width(mm) | C[N] | C0[N] | [r/min] | |

| RNAO 5X10X8 TN | 5 | 10 | 8 | 2289 | 2000 | 40 000 |

| RNAO 6X13X8 TN | 6 | 13 | 8 | 2547 | 2360 | 38 000 |

| RNAO 7X14X8 TN | 7 | 14 | 8 | 2809 | 2747 | 36 000 |

| RNAO 8X15X10 TN | 8 | 15 | 10 | 3796 | 4244 | 36 000 |

| RNAO 10X17X10 TN | 10 | 17 | 10 | 4564 | 5693 | 32 000 |

| RNAO 12X22X12 TN | 12 | 22 | 12 | 9511 | 9991 | 30 000 |

| RNA 4900 | 14 | 22 | 13 | 8791 | 10391 | 28 000 |

| RNA 4900 RS | 14 | 22 | 13 | 7364 | 8142 | 12 000 |

| RNA 4900.2RS | 14 | 22 | 13 | 7364 | 8142 | 12 000 |

| RNAO 15X23X13 | 15 | 23 | 13 | 8244 | 11191 | 28 000 |

| RNA 4901 | 16 | 24 | 13 | 9893 | 12191 | 26 000 |

| RNA 4901 RS | 16 | 24 | 13 | 8084 | 9640 | 11 000 |

| RNA 4901.2RS | 16 | 24 | 13 | 8084 | 9640 | 11 000 |

| RNA 6901 | 16 | 24 | 22 | 16084 | 23182 | 26 000 |

| RNAO 17X25X13 | 17 | 25 | 13 | 10093 | 14587 | 26 000 |

| RNA 4902 | 20 | 28 | 13 | 11191 | 15289 | 22 000 |

| RNA 4902 RS | 20 | 28 | 13 | 9124 | 11991 | 9 500 |

| RNA 4902.2RS | 20 | 28 | 13 | 9124 | 11991 | 9 500 |

| RNA 6902 | 20 | 28 | 23 | 17187 | 26978 | 22 000 |

| RNAO 20X28X26 | 20 | 28 | 26 | 16084 | 28973 | 22 000 |

| RNA 4903 | 22 | 30 | 13 | 11391 | 16284 | 20 000 |

| RNA 4903 RS | 22 | 30 | 13 | 9511 | 12889 | 9 000 |

| RNA 4903.2RS | 22 | 30 | 13 | 9511 | 12889 | 9 000 |

| RNA 6903 | 22 | 30 | 23 | 18684 | 30476 | 20 000 |

| RNAO 22X35X16 | 22 | 35 | 16 | 19382 | 25480 | 19 000 |

| RNA 4904 | 25 | 37 | 17 | 21582 | 27978 | 17 000 |

| RNA 4904 RS | 25 | 37 | 17 | 19382 | 22382 | 7 500 |

| RNA 4904.2RS | 25 | 37 | 17 | 19382 | 22382 | 7 500 |

| RNA 6904 | 25 | 37 | 30 | 35169 | 52956 | 17 000 |

| RNAO 25X35X17 | 25 | 35 | 17 | 14187 | 26476 | 18 000 |

| RNAO 25X35X26 | 25 | 35 | 26 | 18684 | 37467 | 18 000 |

| RNA 49/22 | 28 | 39 | 17 | 23280 | 31973 | 15 000 |

| RNA 69/22 | 28 | 39 | 30 | 36867 | 56951 | 15 000 |

| RNA 4905 | 30 | 42 | 17 | 24178 | 34471 | 15 000 |

| RNA 4905 RS | 30 | 42 | 17 | 21582 | 27476 | 6 300 |

| RNA 4905.2RS | 30 | 42 | 17 | 21582 | 27476 | 6 300 |

| RNA 6905 | 30 | 42 | 30 | 37969 | 61947 | 15 000 |

| RNAO 30X40X17 | 30 | 40 | 17 | 18684 | 33973 | 15 000 |

| RNA 49/28 | 32 | 45 | 17 | 25080 | 36471 | 14 000 |

| RNA 69/28 | 32 | 45 | 30 | 39564 | 65444 | 14 000 |

| RNA 4906 | 35 | 47 | 17 | 25480 | 38969 | 13 000 |

| RNA 4906 RS | 35 | 47 | 17 | 23280 | 31973 | 5 600 |

| RNA 4906.2RS | 35 | 47 | 17 | 23280 | 31973 | 5 600 |

| RNA 6906 | 35 | 47 | 30 | 42862 | 74938 | 13 000 |

| RNA 49/32 | 40 | 52 | 20 | 30773 | 50956 | 11 000 |

| RNA 69/32 | 40 | 52 | 36 | 47258 | 89924 | 11 000 |

| RNAO 40X50X17 | 40 | 50 | 17 | 20484 | 41467 | 12 000 |

| RNAO 40X55X40 | 40 | 55 | 40 | 59351 | 117898 | 11 000 |

| RNA 4907 | 42 | 55 | 20 | 31871 | 53956 | 11 000 |

| RNA 4907 RS | 42 | 55 | 20 | 26978 | 42964 | 4 800 |

| RNA 4907.2RS | 42 | 55 | 20 | 26978 | 42964 | 4 800 |

| RNA 6907 | 42 | 55 | 36 | 48360 | 92920 | 11 000 |

| RNA 4908 | 48 | 62 | 22 | 42862 | 70938 | 9 500 |

| RNA 4908 RS | 48 | 62 | 22 | 36867 | 58449 | 4 000 |

| RNA 4908.2RS | 48 | 62 | 22 | 36867 | 58449 | 4 000 |

| RNA 6908 | 48 | 62 | 40 | 67044 | 124893 | 9 500 |

| RNAO 50X62X20 | 50 | 62 | 20 | 25480 | 59951 | 9 500 |

| RNAO 50X65X20 | 50 | 65 | 20 | 34071 | 61947 | 9 000 |

| RNA 4909 | 52 | 68 | 22 | 45662 | 77933 | 8 500 |

| RNA 4909 RS | 52 | 68 | 22 | 39067 | 63947 | 3 800 |

| RNA 4909.2RS | 52 | 68 | 22 | 39067 | 63947 | 3 800 |

| RNA 6909 | 52 | 68 | 40 | 70342 | 136884 | 8 500 |

| RNAO 55X68X20 | 55 | 68 | 20 | 26978 | 66942 | 8 500 |

| RNA 4910 | 58 | 72 | 22 | 47258 | 84929 | 8 000 |

| RNA 4910 RS | 58 | 72 | 22 | 40164 | 69440 | 3 400 |

| RNA 4910.2RS | 58 | 72 | 22 | 40164 | 69440 | 3 400 |

| RNA 6910 | 58 | 72 | 40 | 73636 | 149871 | 8 000 |

| RNAO 60X78X40 | 60 | 78 | 40 | 72040 | 172853 | 7 500 |

| RNA 4911 | 63 | 80 | 25 | 57151 | 105911 | 7 000 |

| RNA 6911 | 63 | 80 | 45 | 89622 | 189840 | 7 000 |

| RNA 4912 | 68 | 85 | 25 | 60449 | 113902 | 6 700 |

| RNA 6912 | 68 | 85 | 45 | 93422 | 203827 | 6 700 |

| RNA 4913 | 72 | 90 | 25 | 61547 | 119898 | 6 300 |

| RNA 6913 | 72 | 90 | 45 | 95120 | 211818 | 6 300 |

| RNA 4914 | 80 | 100 | 30 | 84129 | 162862 | 5 600 |

| RNA 6914 | 80 | 100 | 54 | 127893 | 284760 | 5 600 |

| RNA 4915 | 85 | 105 | 30 | 84129 | 169858 | 5 300 |

| RNA 6915 | 85 | 105 | 54 | 129889 | 289756 | 5 300 |

| RNA 4916 | 90 | 110 | 30 | 87924 | 182844 | 5 000 |

| RNA 6916 | 90 | 110 | 54 | 133884 | 314733 | 5 000 |

| RNA 4917 | 100 | 120 | 35 | 107907 | 249787 | 4 500 |

| RNA 6917 | 100 | 120 | 63 | 164858 | 424640 | 4 500 |

| RNA 4918 | 105 | 125 | 35 | 111907 | 264773 | 4 300 |

| RNA 6918 | 105 | 125 | 63 | 171853 | 449618 | 4 300 |

| RNA 4919 | 110 | 130 | 35 | 113902 | 269769 | 4 000 |

| RNA 6919 | 110 | 130 | 63 | 171853 | 464604 | 4 000 |

| RNA 4920 | 115 | 140 | 40 | 124893 | 279764 | 4 000 |

| RNA 4822 | 120 | 140 | 30 | 93422 | 231804 | 3 800 |

| RNA 4922 | 125 | 150 | 40 | 129889 | 299747 | 3 600 |

| RNA 4824 | 130 | 150 | 30 | 98916 | 254782 | 3 600 |

| RNA 4924 | 135 | 165 | 45 | 175849 | 404658 | 3 400 |

| RNA 4826 | 145 | 165 | 35 | 118898 | 324724 | 3 200 |

| RNA 4926 | 150 | 180 | 50 | 197831 | 479591 | 3 000 |

| RNA 4828 | 155 | 175 | 35 | 120898 | 344707 | 3 000 |

| RNA 4928 | 160 | 190 | 50 | 204827 | 509569 | 2 800 |

| RNA 4830 | 165 | 190 | 40 | 146876 | 414649 | 2 800 |

| RNA 4832 | 175 | 200 | 40 | 156867 | 449618 | 2 600 |

| RNA 4834 | 185 | 215 | 45 | 178849 | 519560 | 2 400 |

| RNA 4836 | 195 | 225 | 45 | 189840 | 569516 | 2 400 |

| RNA 4838 | 210 | 240 | 50 | 219813 | 709396 | 2 200 |

| RNA 4840 | 220 | 250 | 50 | 223809 | 734378 | 2 000 |

| RNA 4844 | 240 | 270 | 50 | 237800 | 814307 | 1 900 |

| RNA 4848 | 265 | 300 | 60 | 346707 | 1119049 | 1 700 |

| RNA 4852 | 285 | 320 | 60 | 357698 | 1198982 | 1 500 |

| RNA 4856 | 305 | 350 | 69 | 428636 | 1318880 | 1 400 |

| RNA 4860 | 330 | 380 | 80 | 593498 | 1798471 | 1 300 |

| RNA 4872 | 390 | 440 | 80 | 626467 | 2038267 | 1 100 |

| Designation | Principal dimensions | Basic load ratings | Speed | |||

| dynamic | static | Limiting speed | ||||

| Fw | D | C | C[kN] | C0[kN] | [r/min] | |

| BR101812 | 15.875 | 28.575 | 19.050 | 18.9 | 19.7 | 25000 |

| BR122012 | 19.050 | 31.750 | 19.050 | 21.8 | 24.4 | 20000 |

| BR122016 | 19.050 | 31.750 | 25.400 | 27.5 | 33.1 | 20000 |

| BR142212 | 22.225 | 34.925 | 19.050 | 22.9 | 27.1 | 18000 |

| BR142216 | 22.225 | 34.925 | 25.400 | 29.1 | 36.8 | 16000 |

| BR162412 | 25.400 | 38.100 | 19.050 | 25.3 | 31.9 | 16000 |

| BR162416 | 25.400 | 38.100 | 25.400 | 32.1 | 43.3 | 14000 |

| BR182616 | 28.575 | 41.275 | 25.400 | 34.9 | 49.9 | 14000 |

| BR182620 | 28.575 | 41.275 | 31.750 | 43.2 | 65.6 | 13000 |

| BR202816 | 31.750 | 44.450 | 25.400 | 36.0 | 53.4 | 13000 |

| BR202820 | 31.750 | 44.450 | 31.750 | 44.6 | 70.4 | 11000 |

| BR223016 | 34.925 | 47.625 | 25.400 | 38.5 | 60.0 | 11000 |

| BR223020 | 34.925 | 47.625 | 31.750 | 47.7 | 79.0 | 11000 |

| BR243316 | 38.100 | 52.388 | 25.400 | 43.7 | 66.8 | 11000 |

| BR243320 | 38.100 | 52.388 | 31.750 | 54.2 | 88.0 | 9500 |

| BR263516 | 41.275 | 52.388 | 25.450 | 44.8 | 70.9 | 9500 |

| BR263520 | 41.275 | 52.388 | 31.750 | 55.6 | 93.4 | 9000 |

| BR283716 | 44.450 | 58.738 | 25.400 | 47.5 | 78.2 | 9000 |

| BR283720 | 44.450 | 58.738 | 31.750 | 58.9 | 102.9 | 9000 |

| BR283820 | 44.450 | 60.325 | 31.750 | 58.9 | 102.9 | 8500 |

| BR303920 | 47.625 | 61.912 | 31.750 | 60.1 | 107.8 | 8000 |

| BR324116 | 50.800 | 65.088 | 25.400 | 51.0 | 89.3 | 8000 |

| BR324120 | 50.800 | 65.088 | 31.750 | 63.1 | 117.6 | 8000 |

| BR364824 | 57.150 | 76.200 | 38.100 | 90.2 | 157.8 | 7000 |

| BR364828 | 57.150 | 76.200 | 44.450 | 104.9 | 191.1 | 7000 |

| BR405224 | 63.500 | 82.500 | 38.100 | 94.5 | 173.5 | 6500 |

| BR405228 | 63.500 | 82.500 | 44.450 | 109.8 | 209.7 | 6500 |

| BR445624 | 69.850 | 88.900 | 38.100 | 99.0 | 189.1 | 5500 |

| BR445628 | 69.850 | 88.900 | 44.450 | 114.7 | 228.3 | 5500 |

| BR486024 | 76.200 | 95.250 | 38.100 | 104.9 | 211.7 | 5500 |

| BR486028 | 76.200 | 95.250 | 44.450 | 121.5 | 255.8 | 5500 |

| BR526828 | 82.500 | 107.950 | 44.450 | 141.1 | 258.7 | 5000 |

| BR526832 | 82.500 | 107.950 | 50.800 | 153.9 | 289.1 | 5000 |

| BR567232 | 88.900 | 114.300 | 50.800 | 161.7 | 314.6 | 4500 |

| BR607632 | 92.250 | 120.650 | 50.800 | 168.6 | 342.0 | 4000 |

| BR648032 | 101.600 | 127.000 | 50.800 | 176.4 | 367.5 | 4000 |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| dynamic | static | Limiting speed | |||||

| d(mm) | D(mm) | B(mm) | C(mm) | C(N) | C0(N) | [r/min] | |

| NKI 5/12 TN | 5 | 15 | 12 | 3796 | 4244 | 36 000 | |

| NKI 5/16 TN | 5 | 15 | 16 | 5004 | 5844 | 36 000 | |

| NKI 6/12 TN | 6 | 16 | 12 | 4396 | 5196 | 34 000 | |

| NKI 6/16 TN | 6 | 16 | 16 | 5716 | 7196 | 34 000 | |

| NKI 7/12 TN | 7 | 17 | 12 | 4564 | 5693 | 32 000 | |

| NKI 7/16 TN | 7 | 17 | 16 | 5933 | 7991 | 32 000 | |

| NKI 9/12 | 9 | 19 | 12 | 6702 | 8142 | 30 000 | |

| NKI 9/16 | 9 | 19 | 16 | 9124 | 11991 | 30 000 | |

| NKI 10/16 | 10 | 22 | 16 | 10191 | 12489 | 28 000 | |

| NKI 10/20 | 10 | 22 | 20 | 12791 | 16587 | 28 000 | |

| NKI 12/16 | 12 | 24 | 16 | 11689 | 15289 | 26 000 | |

| NKI 12/20 | 12 | 24 | 20 | 14489 | 19982 | 26 000 | |

| NKI 15/16 | 15 | 27 | 16 | 13387 | 18982 | 24 000 | |

| NKI 15/20 | 15 | 27 | 20 | 16484 | 25480 | 24 000 | |

| NKIS 15 | 15 | 35 | 20 | 24578 | 29973 | 19 000 | |

| NKI 17/16 | 17 | 29 | 16 | 13787 | 20382 | 22 000 | |

| NKI 17/20 | 17 | 29 | 20 | 17187 | 26978 | 22 000 | |

| NKIS 17 | 17 | 37 | 20 | 25978 | 33471 | 17 000 | |

| NKI 20/16 | 20 | 32 | 16 | 15387 | 24480 | 19 000 | |

| NKI 20/20 | 20 | 32 | 20 | 18982 | 32471 | 19 000 | |

| NKIS 20 | 20 | 42 | 20 | 28578 | 38969 | 15 000 | |

| NKI 22/16 | 22 | 34 | 16 | 15689 | 25978 | 17 000 | |

| NKI 22/20 | 22 | 34 | 20 | 19382 | 34471 | 17 000 | |

| NKI 25/20 TN | 25 | 38 | 20 | 24578 | 42462 | 15 000 | |

| NKI 25/30 | 25 | 38 | 30 | 31871 | 59951 | 15 000 | |

| NKIS 25 | 25 | 47 | 22 | 34071 | 46462 | 13 000 | |

| NKI 28/20 TN | 28 | 42 | 20 | 26378 | 47960 | 14 000 | |

| NKI 28/30 | 28 | 42 | 30 | 34071 | 65444 | 14 000 | |

| NKI 30/20 TN | 30 | 45 | 20 | 27476 | 51956 | 13 000 | |

| NKI 30/30 TN | 30 | 45 | 30 | 40164 | 84929 | 13 000 | |

| NKIS 30 | 30 | 52 | 22 | 36867 | 53956 | 12 000 | |

| NKI 32/20 | 32 | 47 | 20 | 25080 | 46462 | 12 000 | |

| NKI 32/30 | 32 | 47 | 30 | 36867 | 76436 | 12 000 | |

| NKI 35/20 TN | 35 | 50 | 20 | 29676 | 59951 | 11 000 | |

| NKI 35/30 | 35 | 50 | 30 | 37969 | 82929 | 11 000 | |

| NKIS 35 | 35 | 58 | 22 | 39067 | 60947 | 10 000 | |

| NKI 38/20 | 38 | 53 | 20 | 27476 | 54951 | 11 000 | |

| NKI 38/30 | 38 | 53 | 30 | 40164 | 89924 | 11 000 | |

| NKI 40/20 TN | 40 | 55 | 20 | 31373 | 65444 | 10 000 | |

| NKI 40/30 TN | 40 | 55 | 30 | 45662 | 107907 | 10 000 | |

| NKIS 40 | 40 | 65 | 22 | 42862 | 71938 | 9 000 | |

| NKI 42/20 | 42 | 57 | 20 | 29173 | 60947 | 10 000 | |

| NKI 42/30 | 42 | 57 | 30 | 41764 | 97916 | 10 000 | |

| NKI 45/25 TN | 45 | 62 | 25 | 42862 | 91422 | 9 000 | |

| NKI 45/35 TN | 45 | 62 | 35 | 58249 | 136884 | 9 000 | |

| NKIS 45 | 45 | 72 | 22 | 44560 | 77933 | 8 000 | |

| NKI 50/25 | 50 | 68 | 25 | 40164 | 87924 | 8 500 | |

| NKI 50/35 | 50 | 68 | 35 | 52258 | 121898 | 8 500 | |

| NKIS 50 | 50 | 80 | 28 | 62649 | 103911 | 7 500 | |

| NKI 55/25 TN | 55 | 72 | 25 | 46760 | 109907 | 7 500 | |

| NKI 55/35 | 55 | 72 | 35 | 54951 | 133884 | 7 500 | |

| NKIS 55 | 55 | 85 | 28 | 65942 | 113902 | 6 700 | |

| NKI 60/25 | 60 | 82 | 25 | 43964 | 94920 | 6 700 | |

| NKI 60/35 | 60 | 82 | 35 | 60449 | 145876 | 6 700 | |

| NKIS 60 | 60 | 90 | 28 | 68142 | 119898 | 6 300 | |

| NKI 65/25 | 65 | 90 | 25 | 52756 | 105911 | 6 300 | |

| NKI 65/35 | 65 | 90 | 35 | 73636 | 162862 | 6 300 | |

| NKIS 65 | 65 | 95 | 28 | 70342 | 131889 | 6 000 | |

| NKI 70/25 | 70 | 95 | 25 | 56053 | 126893 | 5 600 | |

| NKI 70/35 | 70 | 95 | 35 | 76436 | 189840 | 5 600 | |

| NKI 75/25 | 75 | 105 | 25 | 69240 | 131889 | 5 300 | |

| NKI 75/35 | 75 | 105 | 35 | 96720 | 199831 | 5 300 | |

| NKI 80/25 | 80 | 110 | 25 | 72040 | 139880 | 5 000 | |

| NKI 80/35 | 80 | 110 | 35 | 100916 | 215818 | 5 000 | |

| NKI 85/26 | 85 | 115 | 26 | 73636 | 145876 | 4 800 | |

| NKI 85/36 | 85 | 115 | 36 | 104911 | 231804 | 4 800 | |

| NKI 90/26 | 90 | 120 | 26 | 76436 | 155867 | 4 500 | |

| NKI 90/36 | 90 | 120 | 36 | 107907 | 249787 | 4 500 | |

| NKI 95/26 | 95 | 125 | 26 | 78036 | 165858 | 4 300 | |

| NKI 95/36 | 95 | 125 | 36 | 111907 | 264773 | 4 300 | |

| NKI 100/30 | 100 | 130 | 30 | 96720 | 219813 | 4 000 | |

| NKI 100/40 | 100 | 130 | 40 | 122893 | 304742 | 4 000 | |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||

| dynamic | static | Limiting speed | |||||

| d(mm) | D(mm) | B(mm) | C(mm) | C(N) | C0(N) | [r/min] | |

| NAO 6X17X10 TN | 6 | 17 | 10 | 4564 | 5693 | 32 000 | |

| NA 4900 | 10 | 22 | 13 | 8791 | 10391 | 28 000 | |

| NA 4900 RS | 10 | 22 | 14 | 13 | 7364 | 8142 | 12 000 |

| NA 4900.2RS | 10 | 22 | 14 | 13 | 7364 | 8142 | 12 000 |

| NA 4901 | 12 | 24 | 13 | 9893 | 12191 | 26 000 | |

| NA 4901 RS | 12 | 24 | 14 | 13 | 8084 | 9640 | 11 000 |

| NA 4901.2RS | 12 | 24 | 14 | 13 | 8084 | 9640 | 11 000 |

| NA 6901 | 12 | 24 | 22 | 16084 | 23182 | 26 000 | |

| NAO 12X24X13 | 12 | 24 | 13 | 8573 | 11991 | 26 000 | |

| NAO 12X28X12 | 12 | 28 | 12 | 10991 | 12489 | 26 000 | |

| NA 4902 | 15 | 28 | 13 | 11191 | 15289 | 22 000 | |

| NA 4902 RS | 15 | 28 | 14 | 13 | 9124 | 11991 | 9 500 |

| NA 4902.2RS | 15 | 28 | 14 | 13 | 9124 | 11991 | 9 500 |

| NA 6902 | 15 | 28 | 23 | 17187 | 26978 | 22 000 | |

| NA 4903 | 17 | 30 | 13 | 11391 | 16284 | 20 000 | |

| NA 4903 RS | 17 | 30 | 14 | 13 | 9511 | 12889 | 9 000 |

| NA 4903.2RS | 17 | 30 | 14 | 13 | 9511 | 12889 | 9 000 |

| NA 6903 | 17 | 30 | 23 | 18684 | 30476 | 20 000 | |

| NAO 17X30X13 | 17 | 30 | 13 | 10093 | 16284 | 20 000 | |

| NAO 17X35X16 | 17 | 35 | 16 | 19382 | 25480 | 19 000 | |

| NA 4904 | 20 | 37 | 17 | 21582 | 27978 | 17 000 | |

| NA 4904 RS | 20 | 37 | 18 | 17 | 19382 | 22382 | 7 500 |

| NA 4904.2RS | 20 | 37 | 18 | 17 | 19382 | 22382 | 7 500 |

| NA 6904 | 20 | 37 | 30 | 35169 | 52956 | 17 000 | |

| NAO 20X35X17 | 20 | 35 | 17 | 14187 | 26476 | 18 000 | |

| NAO 20X37X16 | 20 | 37 | 16 | 20084 | 27978 | 17 000 | |

| NA 49/22 | 22 | 39 | 17 | 23778 | 32471 | 15 000 | |

| NA 69/22 | 22 | 39 | 30 | 36867 | 56951 | 15 000 | |

| NA 4905 | 25 | 42 | 17 | 24578 | 34471 | 15 000 | |

| NA 4905 RS | 25 | 42 | 18 | 17 | 21582 | 27476 | 6 300 |

| NA 4905.2RS | 25 | 42 | 18 | 17 | 21582 | 27476 | 6 300 |

| NA 6905 | 25 | 42 | 30 | 37969 | 61947 | 15 000 | |

| NAO 25X40X17 | 25 | 40 | 17 | 18684 | 33973 | 15 000 | |

| NA 49/28 | 28 | 45 | 17 | 25080 | 37467 | 14 000 | |

| NA 69/28 | 28 | 45 | 30 | 39564 | 65444 | 14 000 | |

| NA 4906 | 30 | 47 | 17 | 25978 | 38969 | 13 000 | |

| NA 4906 RS | 30 | 47 | 18 | 17 | 23280 | 31973 | 5 600 |

| NA 4906.2RS | 30 | 47 | 18 | 17 | 23280 | 31973 | 5 600 |

| NA 6906 | 30 | 47 | 30 | 42862 | 74938 | 13 000 | |

| NAO 30X45X17 | 30 | 45 | 17 | 19782 | 38969 | 13 000 | |

| NAO 30X45X26 | 30 | 45 | 26 | 26378 | 55951 | 13 000 | |

| NAO 30X47X16 | 30 | 47 | 16 | 23280 | 37467 | 13 000 | |

| NA 49/32 | 32 | 52 | 20 | 30773 | 50956 | 11 000 | |

| NA 69/32 | 32 | 52 | 36 | 47258 | 89924 | 11 000 | |

| NA 4907 | 35 | 55 | 20 | 31871 | 53956 | 11 000 | |

| NA 4907 RS | 35 | 55 | 21 | 20 | 26978 | 42964 | 4 800 |

| NA 4907.2RS | 35 | 55 | 21 | 20 | 26978 | 42964 | 4 800 |

| NA 6907 | 35 | 55 | 36 | 48360 | 92920 | 11 000 | |

| NAO 35X50X17 | 35 | 50 | 17 | 20484 | 41467 | 12 000 | |

| NA 4908 | 40 | 62 | 22 | 42862 | 70938 | 9 500 | |

| NA 4908 RS | 40 | 62 | 23 | 22 | 36867 | 58449 | 4 000 |

| NA 4908.2RS | 40 | 62 | 23 | 22 | 36867 | 58449 | 4 000 |

| NA 6908 | 40 | 62 | 40 | 67044 | 124893 | 9 500 | |

| NAO 40X55X17 | 40 | 55 | 17 | 21582 | 46462 | 10 000 | |

| NA 4909 | 45 | 68 | 22 | 45662 | 77933 | 8 500 | |

| NA 4909 RS | 45 | 68 | 22 | 22 | 39067 | 63947 | 3 800 |

| NA 4909.2RS | 45 | 68 | 23 | 22 | 39067 | 63947 | 3 800 |

| NA 6909 | 45 | 68 | 40 | 70342 | 136884 | 8 500 | |

| NA 4910 | 50 | 72 | 22 | 47258 | 84929 | 8 000 | |

| NA 4910 RS | 50 | 72 | 23 | 22 | 40164 | 69440 | 3 400 |

| NA 4910.2RS | 50 | 72 | 23 | 22 | 40164 | 69440 | 3 400 |

| NA 6910 | 50 | 72 | 40 | 73636 | 149871 | 8 000 | |

| NAO 50X68X20 | 50 | 68 | 20 | 26978 | 66942 | 8 500 | |

| NA 4911 | 55 | 80 | 25 | 57151 | 105911 | 7 000 | |

| NA 6911 | 55 | 80 | 45 | 89622 | 189840 | 7 000 | |

| NA 4912 | 60 | 85 | 25 | 60449 | 113902 | 6 700 | |

| NA 6912 | 60 | 85 | 45 | 93422 | 203827 | 6 700 | |

| NA 4913 | 65 | 90 | 25 | 61547 | 119898 | 6 300 | |

| NA 6913 | 65 | 90 | 45 | 95120 | 211818 | 6 300 | |

| NA 4914 | 70 | 100 | 30 | 84129 | 162862 | 5 600 | |

| NA 6914 | 70 | 100 | 54 | 127893 | 284760 | 5 600 | |

| NA 4915 | 75 | 105 | 30 | 84129 | 169858 | 5 300 | |

| NA 6915 | 75 | 105 | 54 | 129889 | 289756 | 5 300 | |

| NA 4916 | 80 | 110 | 30 | 87924 | 182844 | 5 000 | |

| NA 6916 | 80 | 110 | 54 | 133884 | 314733 | 5 000 | |

| NA 4917 | 85 | 120 | 35 | 107907 | 249787 | 4 500 | |

| NA 6917 | 85 | 120 | 63 | 164858 | 424640 | 4 500 | |

| NA 4918 | 90 | 125 | 35 | 111907 | 264773 | 4 300 | |

| NA 6918 | 90 | 125 | 63 | 171853 | 449618 | 4 300 | |

| NA 4919 | 95 | 130 | 35 | 113902 | 269769 | 4 000 | |

| NA 6919 | 95 | 130 | 63 | 171853 | 464604 | 4 000 | |

| NA 4920 | 100 | 140 | 40 | 124893 | 279764 | 4 000 | |

| NA 4822 | 110 | 140 | 30 | 93422 | 231804 | 3 800 | |

| NA 4922 | 110 | 150 | 40 | 129889 | 299747 | 3 600 | |

| NA 4824 | 120 | 150 | 30 | 98916 | 254782 | 3 600 | |

| NA 4924 | 120 | 165 | 45 | 175849 | 404658 | 3 400 | |

| NA 4826 | 130 | 165 | 35 | 118898 | 324724 | 3 200 | |

| NA 4926 | 130 | 180 | 50 | 197831 | 479591 | 3 000 | |

| NA 4828 | 140 | 175 | 35 | 120898 | 344707 | 3 000 | |

| NA 4928 | 140 | 190 | 50 | 204827 | 509569 | 2 800 | |

| NA 4830 | 150 | 190 | 40 | 146876 | 414649 | 2 800 | |

| NA 4832 | 160 | 200 | 40 | 156867 | 449618 | 2 600 | |

| NA 4834 | 170 | 215 | 45 | 178849 | 519560 | 2 400 | |

| NA 4836 | 180 | 225 | 45 | 189840 | 569516 | 2 400 | |

| NA 4838 | 190 | 240 | 50 | 219813 | 709396 | 2 200 | |

| NA 4840 | 200 | 250 | 50 | 223809 | 734378 | 2 000 | |

| NA 4844 | 220 | 270 | 50 | 237800 | 814307 | 1 900 | |

| NA 4848 | 240 | 300 | 60 | 346707 | 1119049 | 1 700 | |

| NA 4852 | 260 | 320 | 60 | 357698 | 1198982 | 1 500 | |

| NA 4856 | 280 | 350 | 69 | 428636 | 1318880 | 1 400 | |

| NA 4860 | 300 | 380 | 80 | 593498 | 1798471 | 1 300 | |

| NA 4864 | 320 | 400 | 80 | 604484 | 1898387 | 1 200 | |

| NA 4868 | 340 | 420 | 80 | 615476 | 1958333 | 1 200 | |

| NA 4872 | 360 | 440 | 80 | 626467 | 2038267 | 1 100 | |

| NA 4876 | 380 | 480 | 100 | 967178 | 2997453 | 1 000 | |

| Designation | Principal dimensions | Basic load ratings | Speed | |||

| dynamic | static | Limiting speed | ||||

| Fw | D | C | C[kN] | C0[kN] | [r/min] | |

| BRI 61812 | 15.875 | 28.575 | 19.050 | 18.9 | 19.7 | 25000 |

| BRI 92012 | 19.050 | 31.750 | 19.050 | 21.8 | 24.4 | 20000 |

| BRI 82016 | 19.050 | 31.750 | 25.400 | 27.5 | 33.1 | 20000 |

| BRI 102212 | 22.225 | 34.925 | 19.050 | 22.9 | 27.1 | 18000 |

| BRI 102216 | 22.225 | 34.925 | 25.400 | 29.1 | 36.8 | 18000 |

| BRI 122412 | 25.400 | 38.100 | 19.050 | 25.3 | 31.9 | 16000 |

| BRI 122416 | 25.400 | 38.100 | 25.400 | 32.1 | 43.3 | 16000 |

| BRI 142616 | 28.575 | 41.275 | 25.400 | 34.9 | 49.9 | 14000 |

| BRI 142620 | 28.575 | 41.275 | 31.750 | 43.2 | 65.6 | 14000 |

| BRI 142620 | 31.750 | 44.450 | 25.400 | 36.0 | 53.4 | 13000 |

| BRI 162816 | 31.750 | 44.450 | 31.750 | 44.6 | 70.4 | 13000 |

| BRI 162820 | 34.925 | 47.625 | 25.400 | 38.5 | 60.0 | 11000 |

| BRI 193020 | 34.925 | 47.625 | 31.750 | 47.7 | 79.0 | 11000 |

| BRI 203316 | 38.100 | 52.388 | 25.400 | 43.7 | 66.8 | 11000 |

| BRI 203320 | 38.100 | 52.388 | 31.750 | 54.2 | 88.0 | 11000 |

| BRI 223516 | 41.275 | 55.562 | 25.450 | 44.8 | 70.9 | 9500 |

| BRI 223520 | 41.275 | 55.562 | 31.750 | 55.6 | 93.4 | 9500 |

| BRI 243716 | 44.450 | 58.738 | 25.450 | 47.5 | 78.2 | 9000 |

| BRI 243720 | 44.450 | 58.738 | 31.750 | 58.9 | 102.9 | 9000 |

| BRI 243820 | 44.450 | 60.325 | 31.750 | 58.9 | 102.9 | 9000 |

| BRI 243920 | 47.625 | 61.912 | 31.750 | 60.1 | 107.8 | 8500 |

| BRI 264116 | 50.800 | 65.088 | 25.400 | 51.0 | 89.3 | 8000 |

| BRI 264120 | 50.800 | 65.088 | 31.750 | 63.1 | 117.6 | 8000 |

| BRI 284824 | 57.150 | 76.200 | 38.100 | 90.2 | 157.8 | 7000 |

| BRI 284828 | 57.150 | 76.200 | 44.450 | 104.9 | 191.1 | 7000 |

| BRI 325224 | 63.500 | 82.550 | 38.100 | 94.5 | 173.5 | 6500 |

| BRI 325228 | 63.500 | 82.550 | 44.450 | 109.8 | 209.7 | 6500 |

| BRI 365624 | 69.850 | 88.900 | 38.100 | 99.0 | 228.3 | 5500 |

| BRI 365628 | 69.850 | 88.900 | 44.450 | 114.7 | 228.3 | 5500 |

| BRI 406024 | 76.200 | 95.250 | 38.100 | 104.9 | 211.7 | 5500 |

| BRI 406028 | 76.200 | 95.250 | 44.450 | 121.5 | 255.8 | 5500 |

| BRI 446828 | 82.550 | 107.950 | 44.450 | 141.1 | 258.7 | 5000 |

| BRI 446832 | 82.550 | 107.950 | 50.800 | 153.9 | 289.1 | 5000 |

| BRI 487232 | 88.900 | 114.300 | 50.800 | 161.7 | 314.6 | 4500 |

| BRI 527632 | 95.250 | 120.650 | 50.800 | 168.6 | 342.0 | 4000 |

| BRI 568032 | 101.600 | 127.000 | 50.800 | 176.4 | 367.5 | 4000 |

Combined Needle Roller Bearing

| Designation | Dimensions | Basic load ratings | Speed | ||||||

| radial dynamic | radial static | axial dynamic | axial static | Limiting speed | |||||

| d[mm] | D[mm] | B[mm] | C[mm] | C[kN] | C0[kN] | C[kN] | C0[kN] | [r/min] | |

| NKIA 5901 | 12 | 24 | 16 | 8.09 | 9.65 | 2.07 | 1.92 | 26 000 | |

| NKIB 5901 | 12 | 24 | 17.5 | 16 | 8.09 | 9.65 | 2.07 | 1.92 | 26 000 |

| NKIA 5902 | 15 | 28 | 18 | 11.2 | 15.3 | 2.27 | 2.37 | 22 000 | |

| NKIB 5902 | 15 | 28 | 20 | 18 | 11.2 | 15.3 | 2.27 | 2.37 | 22 000 |

| NKIA 5903 | 17 | 30 | 18 | 11.4 | 16.3 | 2.24 | 2.74 | 20 000 | |

| NKIB 5903 | 17 | 30 | 20 | 18 | 11.4 | 16.3 | 2.24 | 2.74 | 20 000 |

| NKIA 5904 | 20 | 37 | 23 | 21.6 | 28 | 3.79 | 4.21 | 17 000 | |

| NKIB 5904 | 20 | 37 | 25 | 23 | 21.6 | 28 | 3.79 | 4.21 | 17 000 |

| NKIA 59/22 | 22 | 39 | 23 | 23.3 | 32 | 4.14 | 4.93 | 15 000 | |

| NKIB 59/22 | 22 | 39 | 25 | 23 | 23.3 | 32 | 4.14 | 4.93 | 15 000 |

| NKIA 5905 | 25 | 42 | 23 | 24.2 | 34.5 | 4.24 | 5.26 | 15 000 | |

| NKIB 5905 | 25 | 42 | 25 | 23 | 24.2 | 34.5 | 4.24 | 5.26 | 15 000 |

| NKIA 5906 | 30 | 47 | 23 | 25.5 | 39 | 4.54 | 6.32 | 13 000 | |

| NKIB 5906 | 30 | 47 | 25 | 23 | 25.5 | 39 | 4.54 | 6.32 | 13 000 |

| NKIA 5907 | 35 | 55 | 27 | 31.9 | 54 | 5.83 | 8.42 | 11 000 | |

| NKIB 5907 | 35 | 55 | 30 | 27 | 31.9 | 54 | 5.83 | 8.42 | 11 000 |

| NKIA 5908 | 40 | 62 | 30 | 42.9 | 71 | 7.17 | 10.9 | 9 500 | |

| NKIB 5908 | 40 | 62 | 34 | 30 | 42.9 | 71 | 7.17 | 10.9 | 9 500 |

| NKIA 5909 | 45 | 68 | 30 | 45.7 | 78 | 7.47 | 12 | 8 500 | |

| NKIB 5909 | 45 | 68 | 34 | 30 | 45.7 | 78 | 7.47 | 12 | 8 500 |

| NKIA 5910 | 50 | 72 | 30 | 47.3 | 85 | 7.74 | 13.7 | 8 000 | |

| NKIB 5910 | 50 | 72 | 34 | 30 | 47.3 | 85 | 7.74 | 13.7 | 8 000 |

| NKIA 5911 | 55 | 80 | 34 | 57.2 | 106 | 9.27 | 16.7 | 7 000 | |

| NKIB 5911 | 55 | 80 | 38 | 34 | 57.2 | 106 | 9.27 | 16.7 | 7 000 |

| NKIA 5912 | 60 | 85 | 34 | 60.5 | 114 | 9.58 | 18 | 6 700 | |

| NKIB 5912 | 60 | 85 | 38 | 34 | 60.5 | 114 | 9.58 | 18 | 6 700 |

| NKIA 5913 | 65 | 90 | 34 | 61.6 | 120 | 9.96 | 19.2 | 6 300 | |

| NKIB 5913 | 65 | 90 | 38 | 34 | 61.6 | 120 | 9.96 | 19.2 | 6 300 |

| NKIA 5914 | 70 | 100 | 40 | 84.2 | 163 | 13.2 | 25 | 5 600 | |

| NKIB 5914 | 70 | 100 | 45 | 40 | 84.2 | 163 | 13.2 | 25 | 5 600 |

| Designation | Principal dimensions | Basic load ratings | Speed ratings | ||||||

| radial dynamic | radial static | axial dynamic | axial static | Reference speed | Limiting speed | ||||

| Fw[mm] | D[mm] | C[mm] | C[kN] | C0[kN] | C[kN] | C0[kN] | [r/min] | [r/min] | |

| NX 7 TN | 7 | 14 | 18 | 2.81 | 2.75 | 3.45 | 5 | 32 000 | 36 000 |

| NX 7 ZTN | 7 | 14 | 18 | 2.81 | 2.75 | 3.45 | 5 | 32 000 | 36 000 |

| NKX 10 TN | 10 | 19 | 23 | 5.94 | 8 | 9.95 | 15.3 | 28 000 | 32 000 |

| NKX 10 ZTN | 10 | 19 | 23 | 5.94 | 8 | 9.95 | 15.3 | 28 000 | 32 000 |

| NX 10 | 10 | 19 | 18 | 4.95 | 4.55 | 5.07 | 8.5 | 8 500 | 9 500 |

| NX 10 Z | 10 | 19 | 18 | 4.95 | 4.55 | 5.07 | 8.5 | 8 500 | 5 600 |

| NKX 12 | 12 | 21 | 23 | 9.13 | 12 | 10.4 | 16.6 | 9 000 | 13 000 |

| NKX 12 Z | 12 | 21 | 23 | 9.13 | 12 | 10.4 | 16.6 | 9 000 | 7 500 |

| NX 12 | 12 | 21 | 18 | 5.39 | 5.2 | 5.27 | 9.65 | 8 000 | 9 000 |

| NX 12 Z | 12 | 21 | 18 | 5.39 | 5.2 | 5.27 | 9.65 | 8 000 | 5 300 |

| NKX 15 | 15 | 24 | 23 | 11 | 14 | 10.6 | 18.3 | 8 500 | 12 000 |

| NKX 15 Z | 15 | 24 | 23 | 11 | 14 | 10.6 | 18.3 | 8 500 | 7 000 |

| NKXR 15 | 15 | 24 | 23 | 11 | 14 | 11.2 | 27 | 4 300 | 8 500 |

| NKXR 15 Z | 15 | 24 | 23 | 11 | 14 | 11.2 | 27 | 4 300 | 8 500 |

| NX 15 | 15 | 24 | 28 | 11 | 14 | 6.18 | 12.2 | 7 500 | 8 500 |

| NX 15 Z | 15 | 24 | 28 | 11 | 14 | 6.18 | 12.2 | 7 500 | 5 300 |

| NKX 17 | 17 | 26 | 25 | 12.1 | 16.6 | 10.8 | 19.6 | 8 500 | 12 000 |

| NKX 17 Z | 17 | 26 | 25 | 12.1 | 16.6 | 10.8 | 19.6 | 8 500 | 7 000 |

| NKXR 17 | 17 | 26 | 25 | 12.1 | 16.6 | 12.2 | 31.5 | 4 300 | 8 500 |

| NKXR 17 Z | 17 | 26 | 25 | 12.1 | 16.6 | 12.2 | 31.5 | 4 300 | 8 500 |

| NX 17 | 17 | 26 | 28 | 12.1 | 16.6 | 6.37 | 13.4 | 7 000 | 8 500 |

| NX 17 Z | 17 | 26 | 28 | 12.1 | 16.6 | 6.37 | 13.4 | 7 000 | 5 000 |

| NKX 20 | 20 | 30 | 30 | 16.5 | 25.5 | 14.3 | 27 | 7 500 | 10 000 |

| NKX 20 Z | 20 | 30 | 30 | 16.5 | 25.5 | 14.3 | 27 | 7 500 | 6 000 |

| NKXR 20 | 20 | 30 | 30 | 16.5 | 25.5 | 18.6 | 48 | 3 800 | 7 500 |

| NKXR 20 Z | 20 | 30 | 30 | 16.5 | 25.5 | 18.6 | 48 | 3 800 | 7 500 |

| NX 20 | 20 | 30 | 28 | 13.2 | 19.3 | 7.8 | 17.3 | 6 300 | 7 500 |

| NX 20 Z | 20 | 30 | 28 | 13.2 | 19.3 | 7.8 | 17.3 | 6 300 | 4 500 |

| NKX 25 | 25 | 37 | 30 | 19 | 32.5 | 19.5 | 40.5 | 6 300 | 9 000 |

| NKX 25 Z | 25 | 37 | 30 | 19 | 32.5 | 19.5 | 40.5 | 6 300 | 5 500 |

| NKXR 25 | 25 | 37 | 30 | 19 | 32.5 | 25 | 69.5 | 3 200 | 6 300 |

| NKXR 25 Z | 25 | 37 | 30 | 19 | 32.5 | 25 | 69.5 | 3 200 | 6 300 |

| NX 25 | 25 | 37 | 30 | 15.1 | 24.5 | 12.4 | 28.5 | 5 600 | 6 300 |

| NX 25 Z | 25 | 37 | 30 | 15.1 | 24.5 | 12.4 | 28.5 | 5 600 | 3 800 |

| NKX 30 | 30 | 42 | 30 | 22.9 | 38 | 20.3 | 45.5 | 6 000 | 8 500 |

| NKX 30 Z | 30 | 42 | 30 | 22.9 | 38 | 20.3 | 45.5 | 6 000 | 5 000 |

| NKXR 30 | 30 | 42 | 30 | 22.9 | 38 | 27 | 78 | 3 000 | 6 000 |

| NKXR 30 Z | 30 | 42 | 30 | 22.9 | 38 | 27 | 78 | 3 000 | 6 000 |

| NX 30 | 30 | 42 | 30 | 22.9 | 38 | 12.7 | 32.5 | 5 300 | 6 000 |

| NX 30 Z | 30 | 42 | 30 | 22.9 | 38 | 12.7 | 32.5 | 5 300 | 3 600 |

| NKX 35 | 35 | 47 | 30 | 24.6 | 45 | 21.2 | 51 | 5 600 | 7 500 |

| NKX 35 Z | 35 | 47 | 30 | 24.6 | 45 | 21.2 | 51 | 5 600 | 4 500 |

| NKXR 35 | 35 | 47 | 30 | 24.6 | 45 | 29 | 93 | 2 800 | 5 600 |

| NKXR 35 Z | 35 | 47 | 30 | 24.6 | 45 | 29 | 93 | 2 800 | 5 600 |

| NX 35 | 35 | 47 | 30 | 24.6 | 45 | 13.5 | 38 | 5 000 | 5 600 |

| NX 35 Z | 35 | 47 | 30 | 24.6 | 45 | 13.5 | 38 | 5 000 | 3 400 |

| NKX 40 | 40 | 52 | 32 | 26.4 | 51 | 27 | 68 | 5 000 | 7 000 |

| NKX 40 Z | 40 | 52 | 32 | 26.4 | 51 | 27 | 68 | 5 000 | 4 000 |

| NKXR 40 | 40 | 52 | 32 | 26.4 | 51 | 43 | 137 | 2 400 | 5 000 |

| NKXR 40 Z | 40 | 52 | 32 | 26.4 | 51 | 43 | 137 | 2 400 | 5 000 |

| NKX 45 | 45 | 58 | 32 | 27.5 | 57 | 28.1 | 75 | 4 500 | 6 300 |

| NKX 45 Z | 45 | 58 | 32 | 27.5 | 57 | 28.1 | 75 | 4 500 | 3 800 |

| NKXR 45 | 45 | 58 | 32 | 27.5 | 57 | 45 | 153 | 2 200 | 4 500 |

| NKXR 45 Z | 45 | 58 | 32 | 27.5 | 57 | 45 | 153 | 2 200 | 4 500 |

| NKX 50 | 50 | 62 | 35 | 38 | 78 | 28.6 | 81.5 | 4 300 | 6 300 |

| NKX 50 Z | 50 | 62 | 35 | 38 | 78 | 28.6 | 81.5 | 4 300 | 3 600 |

| NKXR 50 | 50 | 62 | 35 | 38 | 78 | 47.5 | 166 | 2 200 | 4 300 |

| NKXR 50 Z | 50 | 62 | 35 | 38 | 78 | 47.5 | 166 | 2 200 | 4 300 |

| NKX 60 | 60 | 72 | 40 | 41.8 | 96.5 | 41.6 | 122 | 3 600 | 5 000 |

| NKX 60 Z | 60 | 72 | 40 | 41.8 | 96.5 | 41.6 | 122 | 3 600 | 3 000 |

| NKX 70 | 70 | 85 | 40 | 44.6 | 98 | 43.6 | 137 | 3 400 | 4 500 |

| NKX 70 Z | 70 | 85 | 40 | 44.6 | 98 | 43.6 | 137 | 3 400 | 2 700 |

| Designation | Principal dimensions | Basic load ratings | Limiting speed | ||||||||

| d | D | C | B | Radial | Axial | oil | grease | ||||

| mm | mm | mm | mm | C[kN] | C0[kN] | C[kN] | C0[kN] | rpm | rpm | ||

| ZARN 1545TN | ZARN 1545LTN | 15 | 45 | 14.0 | 7.5 | 14.3 | 19.6 | 23.5 | 64.3 | 8500 | 2200 |

| ZARN 1747TN | ZARN 1747LTN | 17 | 47 | 14.0 | 9.0 | 15.4 | 22.1 | 24.3 | 69.3 | 7800 | 2100 |

| ZARN 2052TN | ZARN 2052LTN | 20 | 52 | 14.0 | 10.0 | 14.1 | 20.6 | 27.4 | 77.0 | 7000 | 2000 |

| ZARN 2062TN | ZARN 2062LTN | 20 | 62 | 18.0 | 12.5 | 22.6 | 36.0 | 64.0 | 141.0 | 6000 | 1500 |

| ZARN 2557TN | ZARN 2557LTN | 25 | 57 | 18.0 | 10.0 | 24.8 | 39.8 | 30.5 | 93.5 | 6000 | 1900 |

| ZARN 2572TN | ZARN 2572LTN | 25 | 72 | 18.0 | 12.5 | 24.8 | 41.4 | 80.0 | 199.0 | 4900 | 1400 |

| ZARN 3062TN | ZARN 3062LTN | 30 | 62 | 18.0 | 10.0 | 24.3 | 41.5 | 39.0 | 101.0 | 5500 | 1800 |

| ZARN 3080TN | ZARN 3080LTN | 30 | 80 | 18.0 | 14.0 | 25.9 | 45.8 | 75.7 | 221.0 | 4400 | 1300 |

| ZARN 3570TN | ZARN 3570LTN | 35 | 70 | 18.0 | 11.0 | 26.0 | 47.0 | 45.9 | 105.4 | 4800 | 1700 |

| ZARN 3585TN | ZARN 3585LTN | 35 | 85 | 18.0 | 14.0 | 28.0 | 52.7 | 78.2 | 237.6 | 4000 | 1250 |

| ZARN 4075TN | ZARN 4075LTN | 40 | 75 | 18.0 | 11.0 | 27.5 | 53.0 | 59.0 | 163.0 | 4400 | 1600 |

| ZARN 4090TN | ZARN 4090LTN | 40 | 90 | 22.5 | 16.0 | 40.9 | 72.5 | 84.2 | 269.2 | 3700 | 1200 |

| ZARN 4580TN | ZARN 4580LTN | 45 | 80 | 22.5 | 11.5 | 38.0 | 74.0 | 61.0 | 177.0 | 4000 | 1500 |

| ZARN 45105TN | ZARN 45105LTN | 45 | 105 | 22.5 | 17.5 | 40.0 | 82.0 | 154.0 | 405.0 | 3300 | 1150 |

| ZARN 5090TN | ZARN 5090LTN | 50 | 90 | 22.5 | 11.5 | 40.0 | 82.0 | 90.0 | 300.0 | 3600 | 1200 |

| ZARN 50110TN | ZARN 50110LTN | 50 | 110 | 22.5 | 17.5 | 45.4 | 88.1 | 119.3 | 387.2 | 3100 | 1100 |

| ZARN 55115TN | ZARN 55115LTN | 55 | 115 | 22.5 | 17.5 | 49.0 | 109.9 | 126.0 | 369.0 | 2900 | 1000 |

| ZARN 60120TN | ZARN 60120LTN | 60 | 120 | 22.5 | 17.5 | 54.9 | 1186.0 | 141.0 | 505.0 | 2700 | 950 |

| ZARN 65125TN | ZARN 65125LTN | 65 | 125 | 22.5 | 17.5 | 54.2 | 100.8 | 126.2 | 441.4 | 2600 | 900 |

| ZARN 70130TN | ZARN 70130LTN | 70 | 130 | 22.5 | 17.5 | 69.6 | 143.5 | 143.0 | 532.0 | 2400 | 800 |

| ZARN 75155TN | ZARN 75155LTN | 75 | 155 | 27.0 | 21.0 | 95.0 | 193.0 | 290.0 | 890.0 | 2100 | 700 |

| ZARN 90180TN | ZARN 90180LTN | 90 | 180 | 32.0 | 22.5 | 101.0 | 256.0 | 320.0 | 1172.0 | 1800 | 700 |

| Designation | Principal dimensions | Basic load ratings | Limiting speed | ||||||||

| d | D | C | B | Radial | Axial | oil | grease | ||||

| mm | mm | mm | mm | C[kN] | C0[kN] | C[kN] | C0[kN] | rpm | rpm | ||

| ZARF 1560TN | ZARF 1560LTN | 15 | 60 | 14.0 | 7.5 | 13.0 | 17.5 | 24.9 | 53.0 | 8500 | 2200 |

| ZARF 1762TN | ZARF 1762LTN | 17 | 62 | 14.0 | 9.0 | 14.0 | 19.9 | 26.0 | 57.0 | 7800 | 2100 |

| ZARF 2068TN | ZARF 2068LTN | 20 | 68 | 14.0 | 10.0 | 14.1 | 20.6 | 27.4 | 77.0 | 7000 | 2000 |

| ZARF 2080TN | ZARF 2080LTN | 20 | 80 | 18.0 | 12.5 | 22.6 | 36.0 | 64.0 | 86.0 | 6000 | 1500 |

| ZARF 2575TN | ZARF 2575LTN | 25 | 75 | 18.0 | 10.0 | 24.8 | 39.8 | 30.5 | 93.5 | 6000 | 1900 |

| ZARF 2590TN | ZARF 2590LTN | 25 | 90 | 18.0 | 12.5 | 24.8 | 41.4 | 80.0 | 199.0 | 4900 | 1400 |

| ZARF 3080TN | ZARF 3080LTN | 30 | 80 | 18.0 | 10.0 | 24.3 | 41.0 | 33.9 | 110.0 | 5500 | 1800 |

| ZARF 30105TN | ZARF 30105LTN | 30 | 105 | 18.0 | 14.0 | 25.9 | 45.8 | 75.7 | 221.0 | 4400 | 1300 |

| ZARF 3590TN | ZARF 3590LTN | 35 | 90 | 18.0 | 11.0 | 26.0 | 47.0 | 45.9 | 105.4 | 4800 | 1700 |

| ZARF 35110TN | ZARF 35110LTN | 35 | 110 | 18.0 | 14.0 | 28.0 | 52.7 | 78.2 | 237.6 | 4000 | 1250 |

| ZARF 40100TN | ZARF 40100LTN | 40 | 100 | 18.0 | 11.0 | 30.4 | 58.6 | 51.7 | 180.1 | 4400 | 1600 |

| ZARF 40115TN | ZARF 40115LTN | 40 | 115 | 22.5 | 16.0 | 40.9 | 72.5 | 84.2 | 269.2 | 3700 | 1200 |

| ZARF 45105TN | ZARF 45105LTN | 45 | 105 | 22.5 | 11.5 | 38.0 | 74.0 | 61.0 | 177.0 | 4000 | 1500 |

| ZARF 45130TN | ZARF 45130LTN | 45 | 130 | 22.5 | 17.5 | 42.5 | 78.8 | 115.9 | 363.0 | 3300 | 1150 |

| ZARF 50115TN | ZARF 50115LTN | 50 | 115 | 22.5 | 11.5 | 42.6 | 78.8 | 44.2 | 158.4 | 3600 | 1200 |

| ZARF 50140TN | ZARF 50140LTN | 50 | 140 | 22.5 | 17.5 | 45.5 | 88.1 | 119.3 | 387.2 | 3100 | 1100 |

| ZARF 55145TN | ZARF 55145LTN | 55 | 145 | 22.5 | 17.5 | 49.0 | 109.9 | 126.0 | 369.0 | 2900 | 1000 |

| ZARF 60150TN | ZARF 60150LTN | 60 | 150 | 22.5 | 17.5 | 54.9 | 118.6 | 141.0 | 505.0 | 2700 | 950 |

| ZARF 65155TN | ZARF 65155LTN | 65 | 155 | 22.5 | 17.5 | 54.2 | 100.8 | 126.2 | 441.4 | 2600 | 900 |

| ZARF 70160TN | ZARF 70160LTN | 70 | 160 | 22.5 | 17.5 | 69.6 | 143.5 | 143.0 | 532.0 | 2400 | 800 |

| ZARF 75185TN | ZARF 75185LTN | 75 | 185 | 27.0 | 21.0 | 95.0 | 193.0 | 233.0 | 769.0 | 2100 | 700 |

| ZARF 90210TN | ZARF 90210LTN | 90 | 210 | 32.0 | 22.5 | 101.0 | 2256.0 | 320.0 | 1172.0 | 1800 | 700 |

Yoke-type Track Roller Bearing

| Designation | Principal dimensions | Basic load ratings | |||

| dynamic | static | ||||

| D[mm] | Fw[mm] | C[mm] | C[kN] | C0[kN] | |

| RSTO 5 TN | 16 | 7 | 7.8 | 2.51 | 2.5 |

| RNA 22/6.2RS | 19 | 10 | 11.8 | 4.02 | 3.65 |

| RSTO 6 TN | 19 | 10 | 9.8 | 3.74 | 4.5 |

| RNA 22/8.2RS | 24 | 12 | 11.8 | 4.68 | 4.55 |

| RSTO 8 TN | 24 | 12 | 9.8 | 4.13 | 5.4 |

| RNA 2200.2RS | 30 | 14 | 13.8 | 6.6 | 7.5 |

| RSTO 10 | 30 | 14 | 11.8 | 8.25 | 8.8 |

| RNA 2201.2RS | 32 | 16 | 13.8 | 7.04 | 8.5 |

| RSTO 12 | 32 | 16 | 11.8 | 8.8 | 9.8 |

| RNA 2202.2RS | 35 | 20 | 13.8 | 7.48 | 9.3 |

| RSTO 15 | 35 | 20 | 11.8 | 9.13 | 10.6 |

| RNA 2203.2RS | 40 | 22 | 15.8 | 9.52 | 13.2 |

| RSTO 17 | 40 | 22 | 15.8 | 14.2 | 17.6 |

| RNA 2204.2RS | 47 | 25 | 17.8 | 16.1 | 18 |

| RSTO 20 | 47 | 25 | 15.8 | 16.1 | 21.2 |

| RNA 2205.2RS | 52 | 30 | 17.8 | 16.8 | 20 |

| RSTO 25 | 52 | 30 | 15.8 | 16.5 | 22.8 |

| RNA 2206.2RS | 62 | 35 | 19.8 | 17.9 | 25.5 |

| RSTO 30 | 62 | 38 | 19.8 | 22.9 | 34.5 |

| RNA 2207.2RS | 72 | 42 | 22.7 | 22.4 | 35.5 |

| Designation | Principal dimensions | Basic load ratings | ||||

| dynamic | static | |||||

| D[mm] | d[mm] | C[mm] | B[mm] | C[kN] | C0[kN] | |

| NA 22/6.2RS | 19 | 6 | 11.8 | 12 | 4.02 | 3.65 |

| NA 22/6.2RSX | 19 | 6 | 11.8 | 12 | 4.02 | 3.65 |

| STO 6 TN | 19 | 6 | 9.8 | 10 | 3.74 | 4.5 |

| STO 6 XTN | 19 | 6 | 9.8 | 10 | 3.74 | 4.5 |

| NA 22/8.2RS | 24 | 8 | 11.8 | 12 | 4.68 | 4.55 |

| NA 22/8.2RSX | 24 | 8 | 11.8 | 12 | 4.68 | 4.55 |

| STO 8 TN | 24 | 8 | 9.8 | 10 | 4.13 | 5.4 |

| STO 8 XTN | 24 | 8 | 9.8 | 10 | 4.13 | 5.4 |

| NA 2200.2RS | 30 | 10 | 13.8 | 14 | 6.6 | 7.5 |

| NA 2200.2RSX | 30 | 10 | 13.8 | 14 | 6.6 | 7.5 |

| STO 10 | 30 | 10 | 11.8 | 12 | 8.25 | 8.8 |

| STO 10 X | 30 | 10 | 11.8 | 12 | 8.25 | 8.8 |

| NA 2201.2RS | 32 | 12 | 13.8 | 14 | 7.04 | 8.5 |

| NA 2201.2RSX | 32 | 12 | 13.8 | 14 | 7.04 | 8.5 |

| STO 12 | 32 | 12 | 11.8 | 12 | 8.8 | 9.8 |

| STO 12 X | 32 | 12 | 11.8 | 12 | 8.8 | 9.8 |

| NA 2202.2RS | 35 | 15 | 13.8 | 14 | 7.48 | 9.3 |

| NA 2202.2RSX | 35 | 15 | 13.8 | 14 | 7.48 | 9.3 |

| STO 15 | 35 | 15 | 11.8 | 12 | 9.13 | 10.6 |

| STO 15 X | 35 | 15 | 11.8 | 12 | 9.13 | 10.6 |

| NA 2203.2RS | 40 | 17 | 15.8 | 16 | 9.52 | 13.2 |

| NA 2203.2RSX | 40 | 17 | 15.8 | 16 | 9.52 | 13.2 |

| STO 17 | 40 | 17 | 15.8 | 16 | 14.2 | 17.6 |

| STO 17 X | 40 | 17 | 15.8 | 16 | 14.2 | 17.6 |

| NA 2204.2RS | 47 | 20 | 17.8 | 18 | 16.1 | 18 |

| NA 2204.2RSX | 47 | 20 | 17.8 | 18 | 16.1 | 18 |

| STO 20 | 47 | 20 | 15.8 | 16 | 16.1 | 21.2 |

| STO 20 X | 47 | 20 | 15.8 | 16 | 16.1 | 21.2 |

| NA 2205.2RS | 52 | 25 | 17.8 | 18 | 16.8 | 20 |

| NA 2205.2RSX | 52 | 25 | 17.8 | 18 | 16.8 | 20 |

| STO 25 | 52 | 25 | 15.8 | 16 | 16.5 | 22.8 |

| STO 25 X | 52 | 25 | 15.8 | 16 | 16.5 | 22.8 |

| NA 2206.2RS | 62 | 30 | 19.8 | 20 | 17.9 | 25.5 |

| NA 2206.2RSX | 62 | 30 | 19.8 | 20 | 17.9 | 25.5 |

| STO 30 | 62 | 30 | 19.8 | 20 | 22.9 | 34.5 |

| STO 30 X | 62 | 30 | 19.8 | 20 | 22.9 | 34.5 |

| NA 2207.2RS | 72 | 35 | 22.7 | 23 | 22.4 | 35.5 |

| NA 2207.2RSX | 72 | 35 | 22.7 | 23 | 22.4 | 35.5 |

| STO 35 | 72 | 35 | 19.8 | 20 | 24.6 | 39 |

| STO 35 X | 72 | 35 | 19.8 | 20 | 24.6 | 39 |

| NA 2208.2RS | 80 | 40 | 22.7 | 23 | 27.5 | 40.5 |

| NA 2208.2RSX | 80 | 40 | 22.7 | 23 | 27.5 | 40.5 |

| STO 40 | 80 | 40 | 19.8 | 20 | 23.8 | 39 |

| STO 40 X | 80 | 40 | 19.8 | 20 | 23.8 | 39 |

| NA 2210.2RS | 90 | 50 | 22.7 | 23 | 28.1 | 43 |

| Designation | Dimensions | Basic load ratings | ||||

| dynamic | static | |||||

| D[mm] | d[mm] | C[mm] | B[mm] | C[kN] | C0[kN] | |

| NATR 5 | 16 | 5 | 11 | 12 | 2.86 | 3 |

| NATR 5 PP | 16 | 5 | 11 | 12 | 2.86 | 3 |

| NATR 5 PPX | 16 | 5 | 11 | 12 | 2.86 | 3 |

| NATR 5 X | 16 | 5 | 11 | 12 | 2.86 | 3 |

| NATV 5 | 16 | 5 | 11 | 12 | 4.29 | 6 |

| NATV 5 PP | 16 | 5 | 11 | 12 | 4.29 | 6 |

| NATV 5 PPX | 16 | 5 | 11 | 12 | 4.29 | 6 |

| NATR 6 | 19 | 6 | 11 | 12 | 3.3 | 3.8 |

| NATR 6 PP | 19 | 6 | 11 | 12 | 3.3 | 3.8 |

| NATR 6 PPX | 19 | 6 | 11 | 12 | 3.3 | 3.8 |

| NATR 6 X | 19 | 6 | 11 | 12 | 3.3 | 3.8 |

| NATV 6 | 19 | 6 | 11 | 12 | 4.73 | 7.35 |

| NATV 6 PP | 19 | 6 | 11 | 12 | 4.73 | 7.35 |

| NATV 6 PPX | 19 | 6 | 11 | 12 | 4.73 | 7.35 |

| NATR 8 | 24 | 8 | 14 | 15 | 4.57 | 5.1 |

| NATR 8 PP | 24 | 8 | 14 | 15 | 4.57 | 5.1 |

| NATR 8 PPX | 24 | 8 | 14 | 15 | 4.57 | 5.1 |

| NATR 8 X | 24 | 8 | 14 | 15 | 4.57 | 5.1 |

| NATV 8 | 24 | 8 | 14 | 15 | 7.48 | 11.6 |

| NATV 8 PP | 24 | 8 | 14 | 15 | 7.48 | 11.6 |

| NATV 8 PPX | 24 | 8 | 14 | 15 | 7.48 | 11.6 |

| NATR 10 | 30 | 10 | 14 | 15 | 6.82 | 6.4 |

| NATR 10 PP | 30 | 10 | 14 | 15 | 6.82 | 6.4 |

| NATR 10 PPX | 30 | 10 | 14 | 15 | 6.82 | 6.4 |

| NATR 10 X | 30 | 10 | 14 | 15 | 6.82 | 6.4 |

| NATV 10 | 30 | 10 | 14 | 15 | 10.1 | 13.4 |

| NATV 10 PP | 30 | 10 | 14 | 15 | 10.1 | 13.4 |

| NATV 10 PPX | 30 | 10 | 14 | 15 | 10.1 | 13.4 |

| NATR 12 | 32 | 12 | 14 | 15 | 7.04 | 6.8 |

| NATR 12 PP | 32 | 12 | 14 | 15 | 7.04 | 6.8 |

| NATR 12 PPX | 32 | 12 | 14 | 15 | 7.04 | 6.8 |

| NATR 12 X | 32 | 12 | 14 | 15 | 7.04 | 6.8 |

| NATV 12 | 32 | 12 | 14 | 15 | 10.5 | 14.3 |

| NATV 12 PP | 32 | 12 | 14 | 15 | 10.5 | 14.3 |

| NATV 12 PPX | 32 | 12 | 14 | 15 | 10.5 | 14.3 |

| NATR 15 | 35 | 15 | 18 | 19 | 9.52 | 11.2 |

| NATR 15 PP | 35 | 15 | 18 | 19 | 9.52 | 11.2 |

| NATR 15 PPX | 35 | 15 | 18 | 19 | 9.52 | 11.2 |

| NATR 15 X | 35 | 15 | 18 | 19 | 9.52 | 11.2 |

| NATV 15 | 35 | 15 | 18 | 19 | 13.8 | 21.6 |

| NATV 15 PP | 35 | 15 | 18 | 19 | 13.8 | 21.6 |

| NATV 15 PPX | 35 | 15 | 18 | 19 | 13.8 | 21.6 |

| NUTR 15 A | 35 | 15 | 18 | 19 | 16.8 | 17.6 |

| NUTR 15 X | 35 | 15 | 18 | 19 | 16.8 | 17.6 |

| PWTR 15.2RS | 35 | 15 | 18 | 19 | 11.9 | 11.4 |

| NATR 17 | 40 | 17 | 20 | 21 | 12.5 | 15 |

| NATR 17 PP | 40 | 17 | 20 | 21 | 12.5 | 15 |

| NATR 17 PPX | 40 | 17 | 20 | 21 | 12.5 | 15 |

| NATR 17 X | 40 | 17 | 20 | 21 | 12.5 | 15 |

| NATV 17 | 40 | 17 | 20 | 21 | 17.9 | 28.5 |

| NATV 17 PP | 40 | 17 | 20 | 21 | 17.9 | 28.5 |

| NATV 17 PPX | 40 | 17 | 20 | 21 | 17.9 | 28.5 |

| NUTR 17 A | 40 | 17 | 20 | 21 | 19 | 22 |

| NUTR 17 X | 40 | 17 | 20 | 21 | 19 | 22 |

| PWTR 17.2RS | 40 | 17 | 20 | 21 | 13.8 | 14.3 |

| NUTR 1542 A | 42 | 15 | 18 | 19 | 20.1 | 23.2 |

| NUTR 1542 X | 42 | 15 | 18 | 19 | 20.1 | 23.2 |

| PWTR 1542.2RS | 42 | 15 | 18 | 19 | 14.2 | 15 |

| NATR 20 | 47 | 20 | 24 | 25 | 16.8 | 23.2 |

| NATR 20 PP | 47 | 20 | 24 | 25 | 16.8 | 23.2 |

| NATR 20 PPX | 47 | 20 | 24 | 25 | 16.8 | 23.2 |

| NATV 20 | 47 | 20 | 24 | 25 | 24.6 | 45 |

| NATV 20 PP | 47 | 20 | 24 | 25 | 24.6 | 45 |

| NATV 20 PPX | 47 | 20 | 24 | 25 | 24.6 | 45 |

| NUTR 1747 A | 47 | 17 | 20 | 21 | 22 | 27 |

| NUTR 1747 X | 47 | 17 | 20 | 21 | 22 | 27 |

| NUTR 20 A | 47 | 20 | 24 | 25 | 28.6 | 33.5 |

| NUTR 20 X | 47 | 20 | 24 | 25 | 28.6 | 33.5 |

| PWTR 1747.2RS | 47 | 17 | 20 | 21 | 15.7 | 17.6 |

| PWTR 20.2RS | 47 | 20 | 24 | 25 | 22.9 | 24.5 |

| NATR 25 | 52 | 25 | 24 | 25 | 17.6 | 25 |

| NATR 25 PP | 52 | 25 | 24 | 25 | 17.6 | 25 |

| NATR 25 PPX | 52 | 25 | 24 | 25 | 17.6 | 25 |

| NATR 25 X | 52 | 25 | 24 | 25 | 17.6 | 25 |

| NATV 25 | 52 | 25 | 24 | 25 | 25.5 | 48 |

| NATV 25 PP | 52 | 25 | 24 | 25 | 25.5 | 48 |

| NATV 25 PPX | 52 | 25 | 24 | 25 | 25.5 | 48 |

| NUTR 2052 A | 52 | 20 | 24 | 25 | 31.9 | 39 |

| NUTR 2052 X | 52 | 20 | 24 | 25 | 31.9 | 39 |

| NUTR 25 A | 52 | 25 | 24 | 25 | 29.7 | 36 |

| NUTR 25 X | 52 | 25 | 24 | 25 | 29.7 | 36 |

| PWTR 2052.2RS | 52 | 20 | 24 | 25 | 25.5 | 29 |

| PWTR 25.2RS | 52 | 25 | 24 | 25 | 23.8 | 26.5 |

| NATR 30 | 62 | 30 | 28 | 29 | 22 | 32.5 |

| NATR 30 PP | 62 | 30 | 28 | 29 | 22 | 32.5 |

| NATR 30 PPX | 62 | 30 | 28 | 29 | 22 | 32.5 |

| NATV 30 | 62 | 30 | 28 | 29 | 31.4 | 61 |

| NATV 30 PP | 62 | 30 | 28 | 29 | 31.4 | 61 |

| NATV 30 PPX | 62 | 30 | 28 | 29 | 31.4 | 61 |

| NUTR 2562 A | 62 | 25 | 24 | 25 | 35.8 | 48 |

| NUTR 2562 X | 62 | 25 | 24 | 25 | 35.8 | 48 |

| NUTR 30 A | 62 | 30 | 28 | 29 | 41.3 | 47.5 |

| NUTR 30 X | 62 | 30 | 28 | 29 | 41.3 | 47.5 |

| PWTR 2562.2RS | 62 | 25 | 24 | 25 | 29.2 | 36 |

| PWTR 30.2RS | 62 | 30 | 28 | 29 | 31.9 | 32.5 |

| NATR 35 PP | 72 | 35 | 28 | 29 | 25.5 | 41.5 |

| NATR 35 PPX | 72 | 35 | 28 | 29 | 25.5 | 41.5 |

| NATV 35 PP | 72 | 35 | 28 | 29 | 35.8 | 76.5 |

| NATV 35 PPX | 72 | 35 | 28 | 29 | 35.8 | 76.5 |

| NUTR 3072 A | 72 | 30 | 28 | 29 | 48.4 | 61 |

| NUTR 3072 X | 72 | 30 | 28 | 29 | 48.4 | 61 |

| NUTR 35 A | 72 | 35 | 28 | 29 | 45.7 | 57 |

| NUTR 35 X | 72 | 35 | 28 | 29 | 45.7 | 57 |

| PWTR 3072.2RS | 72 | 30 | 28 | 29 | 39.6 | 45 |

| PWTR 35.2RS | 72 | 35 | 28 | 29 | 35.8 | 40.5 |

| NATR 40 PP | 80 | 40 | 30 | 32 | 29.7 | 53 |

| NATR 40 PPX | 80 | 40 | 30 | 32 | 29.7 | 53 |

| NATV 40 PP | 80 | 40 | 30 | 32 | 40.2 | 93 |

| NATV 40 PPX | 80 | 40 | 30 | 32 | 40.2 | 93 |

| NUTR 3580 A | 80 | 35 | 28 | 29 | 51.2 | 68 |

| NUTR 3580 X | 80 | 35 | 28 | 29 | 51.2 | 68 |

| NUTR 40 A | 80 | 40 | 30 | 32 | 57.2 | 72 |

| NUTR 40 X | 80 | 40 | 30 | 32 | 57.2 | 72 |

| PWTR 3580.2RS | 80 | 35 | 28 | 29 | 41.8 | 50 |

| PWTR 40.2RS | 80 | 40 | 30 | 32 | 41.8 | 49 |

| NUTR 45 A | 85 | 45 | 30 | 32 | 58.3 | 75 |

| NUTR 45 X | 85 | 45 | 30 | 32 | 58.3 | 75 |

| PWTR 45.2RS | 85 | 45 | 30 | 32 | 42.9 | 50 |

| NATR 50 PP | 90 | 50 | 30 | 32 | 29.2 | 53 |

| NATR 50 PPX | 90 | 50 | 30 | 32 | 29.2 | 53 |

| NATV 50 PP | 90 | 50 | 30 | 32 | 39.6 | 96.5 |

| NUTR 4090 A | 90 | 40 | 30 | 32 | 68.2 | 91.5 |

| NUTR 4090 X | 90 | 40 | 30 | 32 | 68.2 | 91.5 |

| NUTR 50 A | 90 | 50 | 30 | 32 | 58.3 | 78 |

| NUTR 50 X | 90 | 50 | 30 | 32 | 58.3 | 78 |

| PWTR 4090.2RS | 90 | 40 | 30 | 32 | 49.5 | 62 |

| PWTR 50.2RS | 90 | 50 | 30 | 32 | 42.9 | 52 |

| NUTR 45100 A | 100 | 45 | 30 | 32 | 73.7 | 104 |

| NUTR 45100 X | 100 | 45 | 30 | 32 | 73.7 | 104 |

| PWTR 45100.2RS | 100 | 45 | 30 | 32 | 53.9 | 69.5 |

| NUTR 50110 A | 110 | 50 | 30 | 32 | 78.1 | 116 |

| NUTR 50110 X | 110 | 50 | 30 | 32 | 78.1 | 116 |

| PWTR 50110.2RS | 110 | 50 | 30 | 32 | 57.2 | 78 |

| Designation | Principal dimensions | Basic load ratings | Speed | |||||

| Normaly type | Sealed type | d | D | B | C | C[kN] | C0[kN] | |

| CRY 12V | CRY 12VUU | 6.350 | 19.050 | 14.288 | 12.700 | 8.7 | 12.3 | 8500 |

| CRY 14V | CRY 14VUU | 6.350 | 22.225 | 14.288 | 12.700 | 8.7 | 12.3 | 8500 |

| CRY 16V | CRY 16VUU | 7.938 | 25.400 | 17.463 | 15.875 | 13.0 | 22.6 | 6300 |

| CRY 18V | CRY 18VUU | 7.938 | 28.575 | 17.463 | 15.875 | 13.0 | 45.7 | 6300 |

| CRY 20V | CRY 20VUU | 9.525 | 31.750 | 20.638 | 19.050 | 23.5 | 31.7 | 5500 |

| CRY 22V | CRY 22VUU | 9.525 | 34.925 | 20.638 | 19.050 | 23.5 | 40.1 | 5500 |

| CRY 24V | CRY 24VUU | 11.112 | 38.100 | 23.813 | 22.225 | 28.1 | 40.1 | 4700 |

| CRY 26V | CRY 26VUU | 11.112 | 41.275 | 23.813 | 22.225 | 28.1 | 40.1 | 4700 |

| CRY 28V | CRY 28VUU | 12.700 | 44.450 | 26.988 | 25.400 | 35.2 | 55.6 | 4000 |

| CRY 30V | CRY 30VUU | 12.700 | 47.625 | 26.988 | 25.400 | 35.2 | 55.6 | 4000 |

| CRY 32V | CRY 32VUU | 15.875 | 50.800 | 33.338 | 31.750 | 45.7 | 80.6 | 3600 |

| CRY 36V | CRY 36VUU | 15.875 | 57.150 | 33.338 | 31.750 | 45.7 | 80.6 | 3600 |

| CRY 40V | CRY 40VUU | 19.050 | 63.500 | 39.688 | 38.100 | 61.3 | 116.6 | 3000 |

| CRY 44V | CRY 44VUU | 19.050 | 68.850 | 39.688 | 38.100 | 61.3 | 116.6 | 3000 |

Cam Followers

| Designation | Principal dimensions | Basic load ratings | |||||

| Unsealed | Sealed | Roller Diameter (inch) | Roller Width (inch) | Stud Diameter(inch) | Stud Length | C0[kN] | C[kN] |

| CF-1/2-N | CF-1/2-N-S | 0.500 | 0.344 | 0.190 | 0.500 | 3.2 | 2.8 |

| CF-1/2 | CF-1/2-S | 0.500 | 0.375 | 0.190 | 0.625 | 3.5 | 3.0 |

| CF-9/16 | CF-9/16-S | 0.5625 | 0.375 | 0.190 | 0.625 | 3.5 | 3.0 |

| CF-5/8-N | CF-5/8-N-S | 0.625 | 0.406 | 0.250 | 0.625 | 4.8 | 4.1 |

| CF-5/8 | CF-5/8-S | 0.625 | 0.4375 | 0.250 | 0.750 | 5.4 | 4.2 |

| CF-11/16 | CF-11/16-S | 0.6875 | 0.4375 | 0.250 | 0.750 | 5.4 | 4.2 |

| CF-3/4 | CF-3/4-S | 0.750 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CF-7/8 | CF-7/8-S | 0.875 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CF-1 | CF-1-S | 1.000 | 0.625 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CF-1 1/8 | CF-1 1/8-S | 1.125 | 0.625 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CF-1 1/4 | CF-1 1/4-S | 1.250 | 0.750 | 0.500 | 1.250 | 18.9 | 17.5 |

| CF-1 3/8 | CF-1 3/8-S | 1.375 | 0.750 | 0.500 | 1.250 | 18.9 | 17.5 |

| CF-1 1/2 | CF-1 1/2-S | 1.500 | 0.875 | 0.625 | 1.500 | 25.1 | 21.5 |

| CF-1 5/8 | CF-1 5/8-S | 1.625 | 0.875 | 0.625 | 1.500 | 25.1 | 21.5 |

| CF-1 3/4 | CF-1 3/4-S | 1.750 | 1.000 | 0.750 | 1.750 | 35.2 | 28.4 |

| CF-1 7/8 | CF-1 7/8-S | 1.875 | 1.000 | 0.750 | 1.750 | 35.2 | 28.4 |

| CF-2 | CF-2-S | 2.000 | 1.250 | 0.875 | 2.000 | 47.0 | 36.0 |

| CF-2 1/4 | CF-2 1/4-S | 2.250 | 1.250 | 0.875 | 2.000 | 47.0 | 36.0 |

| CF-2 1/2 | CF-2 1/2-S | 2.500 | 1.500 | 1.000 | 2.250 | 73.2 | 52.1 |

| CF-2 3/4 | CF-2 3/4-S | 2.750 | 1.500 | 1.000 | 2.250 | 73.2 | 52.1 |

| CF-3 | CF-3-S | 3.000 | 1.750 | 1.250 | 2.500 | 110.8 | 69.9 |

| CF-3 1/4 | CF-3 1/4-S | 3.250 | 1.750 | 1.250 | 2.500 | 110.8 | 69.9 |

| CF-3 1/2 | CF-3 1/2-S | 3.500 | 2.000 | 1.375 | 2.750 | 140.7 | 101.4 |

| CF-4 | CF-4-S | 4.000 | 2.250 | 1.500 | 3.500 | 199.2 | 133.4 |

| CF-5-S | 5.000 | 2.750 | 2.000 | 5.063 | 302.3 | 207.2 | |

| CF-6-S | 6.000 | 3.250 | 2.500 | 6.000 | 357.9 | 267.0 | |

| CF-7-S | 7.000 | 3.750 | 3.000 | 7.688 | 475.8 | 335.4 | |

| CF-8-S | 8.000 | 4.250 | 3.250 | 9.500 | 641.1 | 410.2 | |

| CF-9-S | 9.000 | 4.750 | 3.750 | 9.500 | 816.1 | 503.9 | |

| CF-10-S | 10.000 | 5.250 | 4.250 | 10.000 | 959.1 | 585.3 | |

| CF-1/2-N-B | CF-1/2-N-SB | 0.500 | 0.344 | 0.190 | 0.500 | 3.2 | 2.8 |

| CF-1/2-B | CF-1/2-SB | 0.500 | 0.375 | 0.190 | 0.625 | 3.5 | 3.0 |

| CF-9/16-B | CF-9/16-SB | 0.5625 | 0.375 | 0.190 | 0.625 | 3.5 | 3.0 |

| CF-5/8-N-B | CF-5/8-N-SB | 0.625 | 0.406 | 0.250 | 0.625 | 4.8 | 4.1 |

| CF-5/8-B | CF-5/8-SB | 0.625 | 0.4375 | 0.250 | 0.750 | 5.4 | 4.2 |

| CF-11/16-B | CF-11/16-SB | 0.6875 | 0.4375 | 0.250 | 0.750 | 5.4 | 4.2 |

| CF-3/4-B | CF-3/4-SB | 0.750 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CF-7/8-B | CF-7/8-SB | 0.875 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CF-1-B | CF-1-SB | 1.000 | 0.625 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CF-1 1/8-B | CF-1 1/8-SB | 1.125 | 0.625 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CF-1 1/4-B | CF-1 1/4-SB | 1.250 | 0.750 | 0.500 | 1.250 | 18.9 | 17.5 |

| CF-1 3/8-B | CF-1 3/8-SB | 1.375 | 0.750 | 0.500 | 1.250 | 18.9 | 17.5 |

| CF-1 1/2-B | CF-1 1/2-SB | 1.500 | 0.875 | 0.625 | 1.500 | 25.1 | 21.5 |

| CF-1 5/8-B | CF-1 5/8-SB | 1.625 | 0.875 | 0.625 | 1.500 | 25.1 | 21.5 |

| CF-1 3/4-B | CF-1 3/4-SB | 1.750 | 1.000 | 0.750 | 1.750 | 35.2 | 28.4 |

| CF-1 7/8-B | CF-1 7/8-SB | 1.875 | 1.000 | 0.750 | 1.750 | 35.2 | 28.4 |

| CF-2-B | CF-2-SB | 2.000 | 1.250 | 0.875 | 2.000 | 47.0 | 36.0 |

| CF-2 1/4-B | CF-2 1/4-SB | 2.250 | 1.250 | 0.875 | 2.000 | 47.0 | 36.0 |

| CF-2 1/2-B | CF-2 1/2-SB | 2.500 | 1.500 | 1.000 | 2.250 | 73.2 | 52.1 |

| CF-2 3/4-B | CF-2 3/4-SB | 2.750 | 1.500 | 1.000 | 2.250 | 73.2 | 52.1 |

| CF-3-B | CF-3-SB | 3.000 | 1.750 | 1.250 | 2.500 | 110.8 | 69.9 |

| CF-3 1/4-B | CF-3 1/4-SB | 3.250 | 1.750 | 1.250 | 2.500 | 110.8 | 69.9 |

| CF-3 1/2-B | CF-3 1/2-SB | 3.500 | 2.000 | 1.375 | 2.750 | 140.7 | 101.4 |

| CF-4-B | CF-4-SB | 4.000 | 2.250 | 1.500 | 3.500 | 199.2 | 133.4 |

| 5.000 | 2.750 | 2.000 | 5.063 | 302.3 | 207.2 | ||

| 6.000 | 3.250 | 2.500 | 6.000 | 357.9 | 267.0 | ||

| 7.000 | 3.750 | 3.000 | 7.688 | 475.8 | 335.4 | ||

| 8.000 | 4.250 | 3.250 | 9.500 | 641.1 | 410.2 | ||

| 9.000 | 4.750 | 3.750 | 9.500 | 816.1 | 503.9 | ||

| 10.000 | 5.250 | 4.250 | 10.000 | 959.1 | 585.3 | ||

| Designation | Principal dimensions | Basic load ratings | ||||||

| Unsealed | Sealed | Roller Diameter (inch) | Roller Width (inch) | Bush Length (in) | Stud Diameter(inch) | Stud Length | C0[kN] | C[kN] |

| CFE-1/2 | CFE-1/2-S | 0.500 | 0.375 | 0.250 | 0.190 | 0.625 | 3.5 | 3.0 |

| CFE-9/16 | CFE-9/16-S | 0.5625 | 0.375 | 0.250 | 0.190 | 0.625 | 3.5 | 3.0 |

| CFE-5/8 | CFE-5/8-S | 0.625 | 0.4375 | 0.375 | 0.250 | 0.750 | 5.4 | 4.2 |

| CFE-11/16 | CFE-11/16-S | 0.6875 | 0.4375 | 0.375 | 0.250 | 0.750 | 5.4 | 4.2 |

| CFE-3/4 | CFE-3/4-S | 0.750 | 0.500 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CFE-7/8 | CFE-7/8-S | 0.875 | 0.500 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CFE-1 | CFE-1-S | 1.000 | 0.625 | 0.625 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CFE-1 1/8 | CFE-1 1/8-S | 1.125 | 0.625 | 0.625 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CFE-1 1/4 | CFE-1 1/4-S | 1.250 | 0.750 | 0.687 | 0.500 | 1.250 | 18.9 | 17.5 |

| CFE-1 3/8 | CFE-1 3/8-S | 1.375 | 0.750 | 0.687 | 0.500 | 1.250 | 18.9 | 17.5 |

| CFE-1 1/2 | CFE-1 1/2-S | 1.500 | 0.875 | 0.875 | 0.625 | 1.500 | 25.1 | 21.5 |

| CFE-1 5/8 | CFE-1 5/8-S | 1.625 | 0.875 | 0.875 | 0.625 | 1.500 | 25.1 | 21.5 |

| CFE-1 3/4 | CFE-1 3/4-S | 1.750 | 1.000 | 1.000 | 0.750 | 1.750 | 35.2 | 28.4 |

| CFE-1 7/8 | CFE-1 7/8-S | 1.875 | 1.000 | 1.000 | 0.750 | 1.750 | 35.2 | 28.4 |

| CFE-2 | CFE-2-S | 2.000 | 1.250 | 1.187 | 0.875 | 2.000 | 47.0 | 36.0 |

| CFE-2 1/4 | CFE-2 1/4-S | 2.250 | 1.250 | 1.187 | 0.875 | 2.000 | 47.0 | 36.0 |

| CFE-2 1/2 | CFE-2 1/2-S | 2.500 | 1.500 | 1.375 | 1.000 | 2.250 | 73.2 | 52.1 |

| CFE-2 3/4 | CFE-2 3/4-S | 2.750 | 1.500 | 1.375 | 1.000 | 2.250 | 73.2 | 52.1 |

| CFE-3 | CFE-3-S | 3.000 | 1.750 | 1.750 | 1.250 | 2.500 | 110.8 | 69.9 |

| CFE-3 1/4 | CFE-3 1/4-S | 3.250 | 1.750 | 1.750 | 1.250 | 2.500 | 110.8 | 69.9 |

| CFE-3 1/2 | CFE-3 1/2-S | 3.500 | 2.000 | 1.812 | 1.375 | 2.750 | 140.7 | 101.4 |

| CFE-4 | CFE-4-S | 4.000 | 2.250 | 2.000 | 1.500 | 3.500 | 199.2 | 133.4 |

| CFE-1/2-N-B | CFE-1/2-N-SB | 0.500 | 0.344 | 0.250 | 0.190 | 0.500 | 3.2 | 2.8 |

| CFE-1/2-B | CFE-1/2-SB | 0.500 | 0.375 | 0.375 | 0.190 | 0.625 | 3.5 | 3.0 |

| CFE-9/16-B | CFE-9/16-SB | 0.5625 | 0.375 | 0.375 | 0.190 | 0.625 | 3.5 | 3.0 |

| CFE-5/8-B | CFE-5/8-SB | 0.625 | 0.4375 | 0.437 | 0.250 | 0.750 | 5.4 | 4.2 |

| CFE-11/16-B | CFE-11/16-SB | 0.6875 | 0.4375 | 0.437 | 0.250 | 0.750 | 5.4 | 4.2 |

| CFE-3/4-B | CFE-3/4-SB | 0.750 | 0.500 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CFE-7/8-B | CFE-7/8-SB | 0.875 | 0.500 | 0.500 | 0.375 | 0.875 | 9.2 | 7.4 |

| CFE-1-B | CFE-1-SB | 1.000 | 0.625 | 0.500 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CFE-1 1/8-B | CFE-1 1/8-SB | 1.125 | 0.625 | 0.500 | 0.4375 | 1.000 | 13.6 | 9.9 |

| CFE-1 1/4-B | CFE-1 1/4-SB | 1.250 | 0.750 | 0.625 | 0.500 | 1.250 | 18.9 | 17.5 |

| CFE-1 3/8-B | CFE-1 3/8-SB | 1.375 | 0.750 | 0.625 | 0.500 | 1.250 | 18.9 | 17.5 |

| CFE-1 1/2-B | CFE-1 1/2-SB | 1.500 | 0.875 | 0.750 | 0.625 | 1.500 | 25.1 | 21.5 |

| CFE-1 5/8-B | CFE-1 5/8-SB | 1.625 | 0.875 | 0.750 | 0.625 | 1.500 | 25.1 | 21.5 |

| CFE-1 3/4-B | CFE-1 3/4-SB | 1.750 | 1.000 | 0.875 | 0.750 | 1.750 | 35.2 | 28.4 |

| CFE-1 7/8-B | CFE-1 7/8-SB | 1.875 | 1.000 | 0.875 | 0.750 | 1.750 | 35.2 | 28.4 |

| CFE-2-B | CFE-2-SB | 2.000 | 1.250 | 1.000 | 0.875 | 2.000 | 47.0 | 36.0 |

| CFE-2 1/4-B | CFE-2 1/4-SB | 2.250 | 1.250 | 1.000 | 0.875 | 2.000 | 47.0 | 36.0 |

| CFE-2 1/2-B | CFE-2 1/2-SB | 2.500 | 1.500 | 1.125 | 1.000 | 2.250 | 73.2 | 52.1 |

| CFE-2 3/4-B | CFE-2 3/4-SB | 2.750 | 1.500 | 1.125 | 1.000 | 2.250 | 73.2 | 52.1 |

| CFE-3-B | CFE-3-SB | 3.000 | 1.750 | 1.250 | 1.250 | 2.500 | 110.8 | 69.9 |

| CFE-3 1/4-B | CFE-3 1/4-SB | 3.250 | 1.750 | 1.250 | 1.250 | 2.500 | 110.8 | 69.9 |

| CFE-3 1/2-B | CFE-3 1/2-SB | 3.500 | 2.000 | 1.375 | 1.375 | 2.750 | 140.7 | 101.4 |

| CFE-4-B | CFE-4-SB | 4.000 | 2.250 | 2.000 | 1.500 | 3.500 | 199.2 | 133.4 |

| Designation | Principal dimensions | Basic load ratings | ||||

| dynamic | static | |||||

| D[mm] | d[mm] | B[mm] | C[mm] | C[kN] | C0[kN] | |

| NUKR 35 A | 35 | 16 | 52 | 18 | 16.8 | 17.6 |

| NUKR 35 XA | 35 | 16 | 52 | 18 | 16.8 | 17.6 |

| NUKRE 35 A | 35 | 20 | 52 | 18 | 16.8 | 17.6 |

| PWKR 35.2RS | 35 | 16 | 52 | 18 | 11.9 | 11.4 |

| PWKRE 35.2RS | 35 | 20 | 52 | 18 | 11.9 | 11.4 |

| NUKR 40 A | 40 | 18 | 58 | 20 | 19 | 22 |

| NUKR 40 XA | 40 | 18 | 58 | 20 | 19 | 22 |

| NUKRE 40 A | 40 | 22 | 58 | 20 | 19 | 22 |

| PWKR 40.2RS | 40 | 18 | 58 | 20 | 13.8 | 14.3 |

| PWKRE 40.2RS | 40 | 22 | 58 | 20 | 13.8 | 14.3 |

| NUKR 47 A | 47 | 20 | 66 | 24 | 28.6 | 33.5 |

| NUKR 47 XA | 47 | 20 | 66 | 24 | 28.6 | 33.5 |

| NUKRE 47 A | 47 | 24 | 66 | 24 | 28.6 | 33.5 |

| PWKR 47.2RS | 47 | 20 | 66 | 24 | 22.9 | 24.5 |

| PWKRE 47.2RS | 47 | 24 | 66 | 24 | 22.9 | 24.5 |

| NUKR 52 A | 52 | 20 | 66 | 24 | 29.7 | 36 |

| NUKR 52 XA | 52 | 20 | 66 | 24 | 29.7 | 36 |

| NUKRE 52 A | 52 | 24 | 66 | 24 | 29.7 | 36 |

| PWKR 52.2RS | 52 | 20 | 66 | 24 | 23.8 | 26.5 |

| PWKRE 52.2RS | 52 | 24 | 66 | 24 | 23.8 | 26.5 |

| NUKR 62 A | 62 | 24 | 80 | 28 | 41.3 | 48 |

| NUKR 62 XA | 62 | 24 | 80 | 28 | 41.3 | 48 |

| NUKRE 62 A | 62 | 28 | 80 | 28 | 41.3 | 48 |

| PWKR 62.2RS | 62 | 24 | 80 | 28 | 31.9 | 32.5 |

| PWKRE 62.2RS | 62 | 28 | 80 | 28 | 31.9 | 32.5 |

| NUKR 72 A | 72 | 24 | 80 | 28 | 45.7 | 58.5 |

| NUKR 72 XA | 72 | 24 | 80 | 28 | 45.7 | 58.5 |

| NUKRE 72 A | 72 | 28 | 80 | 28 | 45.7 | 58.5 |

| PWKR 72.2RS | 72 | 24 | 80 | 28 | 39.6 | 45 |

| PWKRE 72.2RS | 72 | 28 | 80 | 28 | 39.6 | 45 |

| NUKR 80 A | 80 | 30 | 100 | 35 | 69.3 | 86.5 |

| NUKR 80 XA | 80 | 30 | 100 | 35 | 69.3 | 86.5 |

| NUKRE 80 A | 80 | 35 | 100 | 35 | 69.3 | 86.5 |

| PWKR 80.2RS | 80 | 30 | 100 | 35 | 57.2 | 73.5 |

| PWKRE 80.2RS | 80 | 35 | 100 | 35 | 57.2 | 73.5 |

| NUKR 90 A | 90 | 30 | 100 | 35 | 78.1 | 102 |

| NUKR 90 XA | 90 | 30 | 100 | 35 | 78.1 | 102 |

| NUKRE 90 A | 90 | 35 | 100 | 35 | 78.1 | 102 |

| PWKR 90.2RS | 90 | 30 | 100 | 35 | 62.7 | 85 |

| PWKRE 90.2RS | 90 | 35 | 100 | 35 | 62.7 | 85 |

| Designation | Principal dimensions | Basic load ratings | ||||

| dynamic | static | |||||

| D[mm] | d[mm] | B[mm] | C[mm] | C[kN] | C0[kN] | |

| KR 16 | 16 | 6 | 28.2 | 11 | 2.92 | 3.1 |

| KR 16 PP | 16 | 6 | 28.2 | 11 | 2.92 | 3.1 |

| KR 16 PPX | 16 | 6 | 28.2 | 11 | 2.92 | 3.1 |

| KR 16 X | 16 | 6 | 28.2 | 11 | 2.92 | 3.1 |

| KRE 16 PP | 16 | 9 | 28.2 | 11 | 2.92 | 3.1 |

| KRV 16 | 16 | 6 | 28.2 | 11 | 4.57 | 6.4 |

| KRV 16 PP | 16 | 6 | 28.2 | 11 | 4.57 | 6.4 |

| KRV 16 PPX | 16 | 6 | 28.2 | 11 | 4.57 | 6.4 |

| KRVE 16 PP | 16 | 9 | 28.2 | 11 | 4.57 | 6.4 |

| KR 19 | 19 | 8 | 32.2 | 11 | 3.3 | 3.8 |

| KR 19 PP | 19 | 8 | 32.2 | 11 | 3.3 | 3.8 |

| KR 19 PPX | 19 | 8 | 32.2 | 11 | 3.3 | 3.8 |

| KR 19 X | 19 | 8 | 32.2 | 11 | 3.3 | 3.8 |

| KRE 19 PP | 19 | 11 | 32.2 | 11 | 3.3 | 3.8 |

| KRV 19 | 19 | 8 | 32.2 | 11 | 5.01 | 7.8 |

| KRV 19 PP | 19 | 8 | 32.2 | 11 | 5.01 | 7.8 |

| KRV 19 PPX | 19 | 8 | 32.2 | 11 | 5.01 | 7.8 |

| KRVE 19 PP | 19 | 11 | 32.2 | 11 | 5.01 | 7.8 |

| KR 22 | 22 | 10 | 36.2 | 12 | 3.96 | 5 |

| KR 22 PP | 22 | 10 | 36.2 | 12 | 3.96 | 5 |

| KR 22 PPX | 22 | 10 | 36.2 | 12 | 3.96 | 5 |

| KR 22 X | 22 | 10 | 36.2 | 12 | 3.96 | 5 |

| KRE 22 PP | 22 | 13 | 36.2 | 12 | 3.96 | 5 |

| KRV 22 | 22 | 10 | 36.2 | 12 | 5.61 | 9.5 |

| KRV 22 PP | 22 | 10 | 36.2 | 12 | 5.61 | 9.5 |

| KRV 22 PPX | 22 | 10 | 36.2 | 12 | 5.61 | 9.5 |

| KRV 22 X | 22 | 10 | 36.2 | 12 | 5.61 | 9.5 |

| KRVE 22 PP | 22 | 13 | 36.2 | 12 | 5.61 | 9.5 |

| KR 26 | 26 | 10 | 36.2 | 12 | 4.46 | 6.1 |

| KR 26 PP | 26 | 10 | 36.2 | 12 | 4.46 | 6.1 |

| KR 26 PPX | 26 | 10 | 36.2 | 12 | 4.46 | 6.1 |

| KR 26 X | 26 | 10 | 36.2 | 12 | 4.46 | 6.1 |

| KRE 26 PP | 26 | 13 | 36.2 | 12 | 4.46 | 6.1 |

| KRV 26 | 26 | 10 | 36.2 | 12 | 6.44 | 11.6 |

| KRV 26 PP | 26 | 10 | 36.2 | 12 | 6.44 | 11.6 |

| KRV 26 PPX | 26 | 10 | 36.2 | 12 | 6.44 | 11.6 |

| KRVE 26 PP | 26 | 13 | 36.2 | 12 | 6.44 | 11.6 |

| KR 30 | 30 | 12 | 40.2 | 14 | 6.16 | 8 |

| KR 30 PP | 30 | 12 | 40.2 | 14 | 6.16 | 8 |

| KR 30 PPX | 30 | 12 | 40.2 | 14 | 6.16 | 8 |

| KR 30 X | 30 | 12 | 40.2 | 14 | 6.16 | 8 |

| KRE 30 PP | 30 | 15 | 40.2 | 14 | 6.16 | 8 |

| KRV 30 | 30 | 12 | 40.2 | 14 | 8.58 | 14.6 |

| KRV 30 PP | 30 | 12 | 40.2 | 14 | 8.58 | 14.6 |

| KRV 30 PPX | 30 | 12 | 40.2 | 14 | 8.58 | 14.6 |

| KRVE 30 PP | 30 | 15 | 40.2 | 14 | 8.58 | 14.6 |

| KR 32 | 32 | 12 | 40.2 | 14 | 6.44 | 8.5 |

| KR 32 PP | 32 | 12 | 40.2 | 14 | 6.44 | 8.5 |

| KR 32 PPX | 32 | 12 | 40.2 | 14 | 6.44 | 8.5 |

| KR 32 X | 32 | 12 | 40.2 | 14 | 6.44 | 8.5 |

| KRE 32 PP | 32 | 15 | 40.2 | 14 | 6.44 | 8.5 |

| KRV 32 | 32 | 12 | 40.2 | 14 | 9.13 | 15.6 |

| KRV 32 PP | 32 | 12 | 40.2 | 14 | 9.13 | 15.6 |

| KRV 32 PPX | 32 | 12 | 40.2 | 14 | 9.13 | 15.6 |

| KRVE 32 PP | 32 | 15 | 40.2 | 14 | 9.13 | 15.6 |

| KR 35 | 35 | 16 | 52.1 | 18 | 8.58 | 12.9 |

| KR 35 PP | 35 | 16 | 52.1 | 18 | 8.58 | 12.9 |

| KR 35 PPX | 35 | 16 | 52.1 | 18 | 8.58 | 12.9 |

| KR 35 X | 35 | 16 | 52.1 | 18 | 8.58 | 12.9 |

| KRE 35 PP | 35 | 20 | 52.1 | 18 | 8.58 | 12.9 |

| KRV 35 PP | 35 | 16 | 52.1 | 18 | 11.9 | 23.6 |

| KRV 35 PPX | 35 | 16 | 52.1 | 18 | 11.9 | 23.6 |

| KRVE 35 PP | 35 | 20 | 52.1 | 18 | 11.9 | 23.6 |

| KR 40 | 40 | 18 | 58.1 | 20 | 10.2 | 17 |

| KR 40 PP | 40 | 18 | 58.1 | 20 | 10.2 | 17 |

| KR 40 PPX | 40 | 18 | 58.1 | 20 | 10.2 | 17 |

| KR 40 X | 40 | 18 | 58.1 | 20 | 10.2 | 17 |

| KRE 40 PP | 40 | 22 | 58.1 | 20 | 10.2 | 17 |

| KRV 40 PP | 40 | 18 | 58.1 | 20 | 14 | 31 |

| KRV 40 PPX | 40 | 18 | 58.1 | 20 | 14 | 31 |

| KRVE 40 PP | 40 | 22 | 58.1 | 20 | 14 | 31 |

| KR 47 | 47 | 20 | 66.1 | 24 | 14.7 | 25 |

| KR 47 PP | 47 | 20 | 66.1 | 24 | 14.7 | 25 |

| KR 47 PPX | 47 | 20 | 66.1 | 24 | 14.7 | 25 |

| KR 47 X | 47 | 20 | 66.1 | 24 | 14.7 | 25 |

| KRE 47 PP | 47 | 24 | 66.1 | 24 | 14.7 | 25 |

| KRV 47 PP | 47 | 20 | 66.1 | 24 | 19.4 | 41.5 |

| KRV 47 PPX | 47 | 20 | 66.1 | 24 | 19.4 | 41.5 |

| KRVE 47 PP | 47 | 24 | 66.1 | 24 | 19.4 | 41.5 |

| KR 52 | 52 | 20 | 66.1 | 24 | 16.1 | 28 |

| KR 52 PP | 52 | 20 | 66.1 | 24 | 16.1 | 28 |

| KR 52 PPX | 52 | 20 | 66.1 | 24 | 16.1 | 28 |

| KR 52 X | 52 | 20 | 66.1 | 24 | 16.1 | 28 |

| KRE 52 PP | 52 | 24 | 66.1 | 24 | 16.1 | 28 |

| KRV 52 PP | 52 | 20 | 66.1 | 24 | 21.2 | 48 |

| KRV 52 PPX | 52 | 20 | 66.1 | 24 | 21.2 | 48 |

| KRVE 52 PP | 52 | 24 | 66.1 | 24 | 21.2 | 48 |

| KR 62 | 62 | 24 | 80.1 | 29 | 24.2 | 44 |

| KR 62 PP | 62 | 24 | 80.1 | 29 | 24.2 | 44 |

| KR 62 PPX | 62 | 24 | 80.1 | 29 | 24.2 | 44 |

| KR 62 X | 62 | 24 | 80.1 | 29 | 24.2 | 44 |

| KRE 62 PP | 62 | 28 | 80.1 | 29 | 24.2 | 44 |

| KRV 62 PP | 62 | 24 | 80.1 | 29 | 30.3 | 69.5 |

| KRV 62 PPX | 62 | 24 | 80.1 | 29 | 30.3 | 69.5 |

| KRVE 62 PP | 62 | 28 | 80.1 | 29 | 30.3 | 69.5 |

| KR 72 | 72 | 24 | 80.1 | 29 | 25.5 | 48 |

| KR 72 PP | 72 | 24 | 80.1 | 29 | 25.5 | 48 |

| KR 72 PPX | 72 | 24 | 80.1 | 29 | 25.5 | 48 |

| KR 72 X | 72 | 24 | 80.1 | 29 | 25.5 | 48 |

| KRE 72 PP | 72 | 28 | 80.1 | 29 | 25.5 | 48 |

| KRV 72 PP | 72 | 24 | 80.1 | 29 | 33 | 78 |

| KRV 72 PPX | 72 | 24 | 80.1 | 29 | 33 | 78 |

| KRVE 72 PP | 72 | 28 | 80.1 | 29 | 33 | 78 |

| KR 80 | 80 | 30 | 100 | 35 | 35.8 | 71 |

| KR 80 PP | 80 | 30 | 100 | 35 | 35.8 | 71 |

| KR 80 PPX | 80 | 30 | 100 | 35 | 35.8 | 71 |

| KR 80 X | 80 | 30 | 100 | 35 | 35.8 | 71 |

| KRE 80 PP | 80 | 35 | 100 | 35 | 35.8 | 71 |

| KRV 80 PP | 80 | 30 | 100 | 35 | 44.6 | 112 |

| KRV 80 PPX | 80 | 30 | 100 | 35 | 44.6 | 112 |

| KRVE 80 PP | 80 | 35 | 100 | 35 | 44.6 | 112 |

| KR 90 | 90 | 30 | 100 | 35 | 38 | 76.5 |

| KR 90 PP | 90 | 30 | 100 | 35 | 38 | 76.5 |

| KR 90 PPX | 90 | 30 | 100 | 35 | 38 | 76.5 |

| KR 90 X | 90 | 30 | 100 | 35 | 38 | 76.5 |

| KRE 90 PP | 90 | 35 | 100 | 35 | 38 | 76.5 |

| KRV 90 PP | 90 | 30 | 100 | 35 | 46.8 | 122 |

| KRV 90 PPX | 90 | 30 | 100 | 35 | 46.8 | 122 |

| KRVE 90 PP | 90 | 35 | 100 | 35 | 46.8 | 122 |

Needle Roller Bearing Inner Ring

| Designation | Principal dimensions | ||

| d[mm] | F[mm] | B[mm] | |

| IR 5X8X12 | 5 | 8 | 12 |

| IR 5X8X16 | 5 | 8 | 16 |

| IR 6X10X10 | 6 | 10 | 10 |

| IR 6X10X10 IS1 | 6 | 10 | 10 |

| IR 6X9X12 | 6 | 9 | 12 |

| IR 6X9X16 | 6 | 9 | 16 |

| IR 7X10X10.5 | 7 | 10 | 10.5 |

| IR 7X10X12 | 7 | 10 | 12 |

| IR 7X10X16 | 7 | 10 | 16 |

| LR 7X10X10.5 | 7 | 10 | 10.5 |

| IR 8X12X10 | 8 | 12 | 10 |

| IR 8X12X10 IS1 | 8 | 12 | 10 |

| IR 8X12X10.5 | 8 | 12 | 10.5 |

| IR 8X12X12.5 | 8 | 12 | 12.5 |

| LR 8X12X10.5 | 8 | 12 | 10.5 |

| IR 9X12X12 | 9 | 12 | 12 |

| IR 9X12X16 | 9 | 12 | 16 |

| IR 10X13X12.5 | 10 | 13 | 12.5 |

| IR 10X14X12 IS1 | 10 | 14 | 12 |

| IR 10X14X13 | 10 | 14 | 13 |

| IR 10X14X16 | 10 | 14 | 16 |

| IR 10X14X20 | 10 | 14 | 20 |

| LR 10X13X12.5 | 10 | 13 | 12.5 |

| IR 12X15X12 | 12 | 15 | 12 |

| IR 12X15X12.5 | 12 | 15 | 12.5 |

| IR 12X15X16 | 12 | 15 | 16 |

| IR 12X15X16.5 | 12 | 15 | 16.5 |

| IR 12X15X22.5 | 12 | 15 | 22.5 |

| IR 12X16X12 IS1 | 12 | 16 | 12 |

| IR 12X16X13 | 12 | 16 | 13 |

| IR 12X16X16 | 12 | 16 | 16 |

| IR 12X16X20 | 12 | 16 | 20 |

| IR 12X16X22 | 12 | 16 | 22 |

| LR 12X15X12.5 | 12 | 15 | 12.5 |

| LR 12X15X22.5 | 12 | 15 | 22.5 |

| IR 14X17X17 | 14 | 17 | 17 |

| IR 15X18X16 | 15 | 18 | 16 |

| IR 15X18X16.5 | 15 | 18 | 16.5 |

| IR 15X19X16 | 15 | 19 | 16 |

| IR 15X19X20 | 15 | 19 | 20 |

| IR 15X20X12 IS1 | 15 | 20 | 12 |

| IR 15X20X13 | 15 | 20 | 13 |

| IR 15X20X23 | 15 | 20 | 23 |

| LR 15X18X12.5 | 15 | 18 | 12.5 |

| IR 17X20X16 | 17 | 20 | 16 |

| IR 17X20X16.5 | 17 | 20 | 16.5 |

| IR 17X20X20 | 17 | 20 | 20 |

| IR 17X20X20.5 | 17 | 20 | 20.5 |

| IR 17X20X30.5 | 17 | 20 | 30.5 |

| IR 17X21X16 | 17 | 21 | 16 |

| IR 17X21X20 | 17 | 21 | 20 |

| IR 17X22X13 | 17 | 22 | 13 |

| IR 17X22X16 | 17 | 22 | 16 |

| IR 17X22X23 | 17 | 22 | 23 |

| IR 17X24X20 | 17 | 24 | 20 |

| LR 17X20X16.5 | 17 | 20 | 16.5 |

| LR 17X20X20.5 | 17 | 20 | 20.5 |

| LR 17X20X30.5 | 17 | 20 | 30.5 |

| IR 20X24X16 | 20 | 24 | 16 |

| IR 20X24X20 | 20 | 24 | 20 |