Bearings Manufacturer

ZMS is a professional bearings manufacturer and exporter in China. we apply our 15 years of engineering and manufacturing experience to meet customers’ demands of bearing challenges.

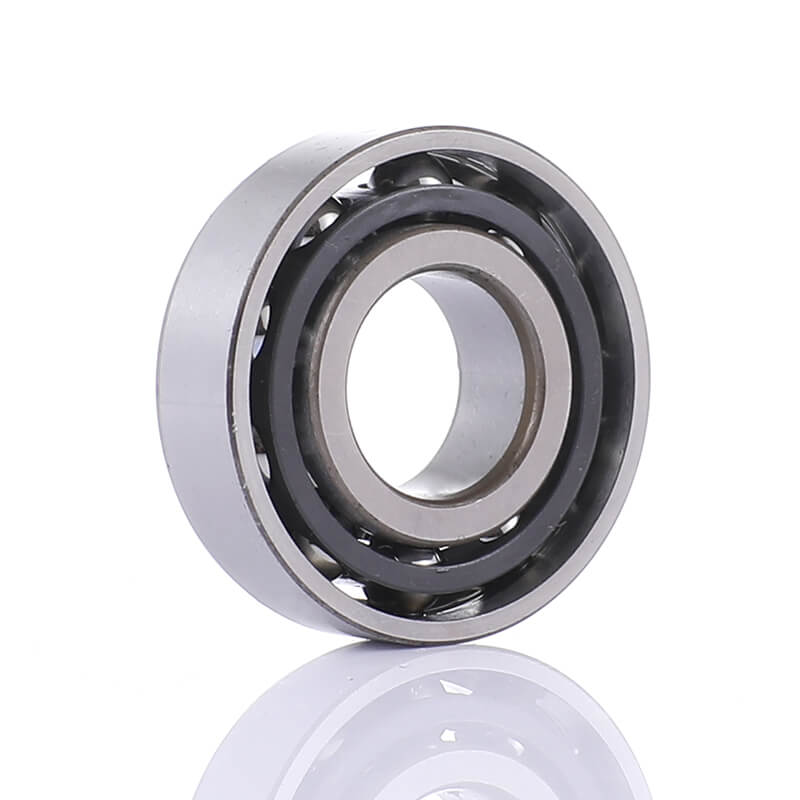

We supply high quality bearings in China. Including thin section bearings, custom bearings, deep groove ball bearings, needle roller bearings, angular contact ball bearings, tapered roller bearings, large size bearings, mounted bearings and so on.

6 advantages of using ZMS products

Raw material

Cutting

CNC turning

Heat treatment

Grinding

Super fine

Assembling

Inspection

Demagnetization

Cleaning

Marking

Stocking