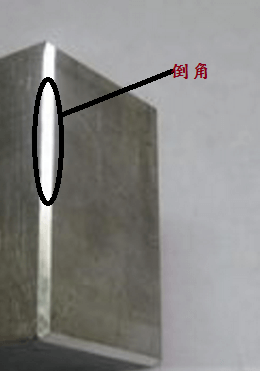

Chamfering is a term in mechanical engineering. In order to remove burrs on parts caused by machining and to facilitate the assembly of parts, chamfering is generally made at the end of the part.

Chamfering can be seen everywhere in our lives, on mobile phone frames, tempered doors, vases, etc.

Generally, the function of chamfering is to remove burrs and make them beautiful.

However, the chamfers specifically pointed out in the drawings are generally requirements for the installation process, such as the installation guide for bearings. There are also some arc chamfers (or arc transitions) that can also reduce stress concentration and strengthen the shaft. The role of the strength of the part.

In addition, it can also make assembly easier, usually before the end of processing.

On agricultural machinery parts, especially the end faces of circular fittings and round holes are often processed into chamfers of about 45°.

These chamfers have many functions. They must be carefully checked and fully utilized during maintenance operations. Otherwise, it will bring many difficulties to the maintenance of agricultural machinery and even cause unexpected failures. For example, before the molding process of small parts such as bolts, chamfering is also performed to facilitate entry into the mold.

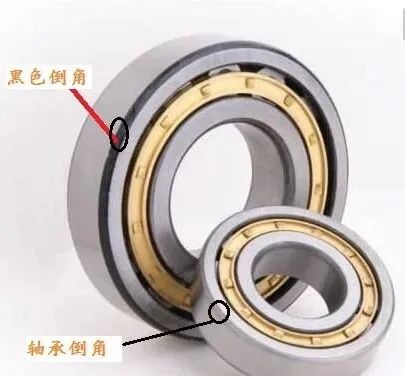

What is the function of bearing chamfering?

1.Bearing steel must be chamfered during rough machining before heat treatment. In this way, during the heat treatment of the material, stress is released and the internal organizational structure is redistributed, making cracks less likely to occur.

2.Chamfering and deburring make the product non-sharp and will not cut the user.

3.It plays a guiding and positioning role during assembly.

Usually the outer chamfer of the outer ring of the bearing and the inner chamfer of the inner ring are rounded corners. In addition to effectively avoiding contact stress, the most important thing is to facilitate installation. Rounded corners ensure a good transitional fit.

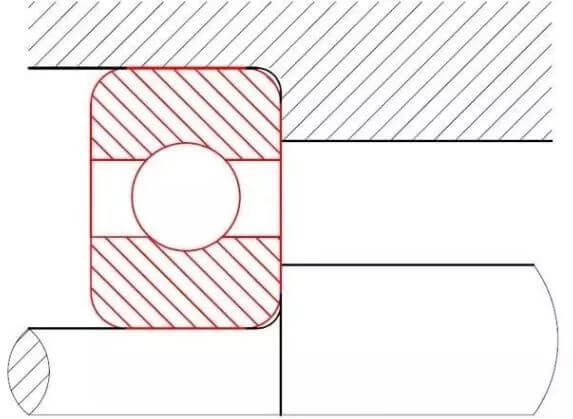

Especially during the bearing process, the matching positioning surface of the shaft and the shaft hole, that is, the shaft shoulder and the bearing seat shoulder part, the chamfer size of this part directly affects whether the bearing can be installed correctly.

From the picture above, we can see that the bearing is installed between the axle box and the shaft. The chamfers are larger than the chamfers between the bearing box and the shaft shoulder. The chamfer of the bearing must be larger than this arc to ensure that the bearing fits the shaft. towards the positioning surface.

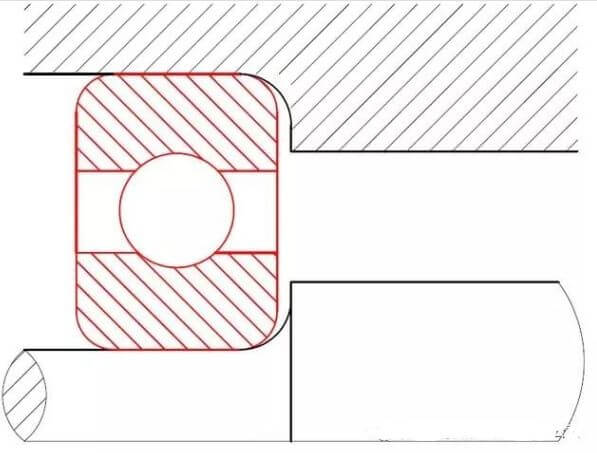

As shown in the figure above, when the chamfer of the bearing is smaller than the chamfer of the bearing box and the shaft shoulder, it cannot be assembled in place, which can easily cause stress concentration at the chamfer of the bearing, tilt of the assembly, and the inability to match other mating parts.

Therefore, the chamfer fit must be fully considered during the assembly process of the bearing.

Leave A Comment