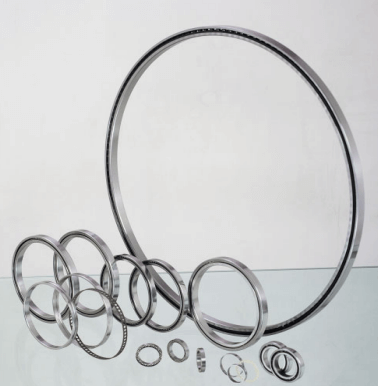

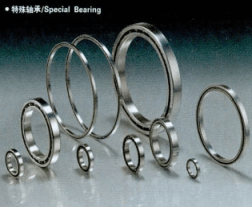

Industrial robot bearings, to be precise, should be called bearings for industrial robots. They mainly include: thin-walled ball bearings, crossed cylindrical roller bearings, harmonic reducer flexible bearings, etc.

1.Development status of industrial robot bearings

As one of the key supporting basic components of industrial robots, industrial robot bearings are still a relatively weak link in our country. The existing national standards for bearings cannot meet and guide the design, production and inspection of industrial robot bearings.

Luoyang Weisge Bearing Co., Ltd. has been committed to the research and development of industrial robot bearings for many years. It has now formed three series of products: thin-walled bearings with equal cross-section, crossed cylindrical roller bearings, and flexible bearings for harmonic reducers. The products range from inner diameter to It can be manufactured from Φ15 mm to outer diameter Φ650 mm, with precision from P0 to P2, which can fully meet the needs of industrial robot OEMs.

In the development and production practice of industrial robot bearings, in order to standardize and serialize the production of industrial robot bearings, the company has successively compiled samples of equal-section thin-walled bearings for industrial robots, samples of lightweight crossed cylindrical roller bearings, and flexible bearings for harmonic reducers. Samples, product technical standards were formulated, which were reviewed by experts and filed with the Bureau of Quality and Technical Supervision, filling the domestic gap and integrating with international standards.

The company’s equal-section thin-wall bearing series products were recognized as high-tech products in 2004, and the company was recognized as a high-tech enterprise. In 2006, the company was recognized by the Ministry of Science and Technology as the unit undertaking the National Torch Plan project, and won the National Innovative Small and Medium Enterprise Development Award that year. Fund support.

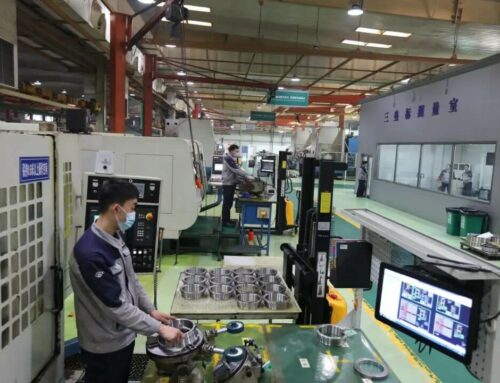

At present, Luoyang Weisge Bearing Co., Ltd. specializes in the research and development of industrial robot bearings. In the past ten years, it has produced and sold nearly 200,000 sets of various robot bearings, which are exported to Europe, the United States, Japan, South Korea, Singapore, Taiwan, China and other countries and regions. At the same time, It also provides product supporting and technical support services to many domestic enterprises and scientific research institutions engaged in the R&D and production of industrial robots and parts.

2. Applications and suggestions

According to statistics, China has the largest number of people engaged in robot research in the world, and the research time is also very long. However, the irony is that it still has not mastered the core technology of robots. Key basic components of industrial robots such as drives, AC/DC servo motors, and precision reducers are still dependent on imports, which has become a bottleneck for the development of industrial robots in China. Faced with this situation, there have even been voices questioning whether industrial robots should still be developed in China?

For the benefit of the country and the rejuvenation of the nation, we are indeed full of confidence and expectations in Chinese industrial robots.

According to Wang Weiming, deputy director of the Equipment Industry Department of the Ministry of Industry and Information Technology, the Ministry of Industry and Information Technology and the Ministry of Finance are coordinating and considering relevant support policies for the development of three key components in the field of robots: drives, motors, and reducers. Regarding the future of localization of key components, Qu Daokui, deputy director of the National Robotics Engineering Research Center and chairman of the China Robot Industry Innovation Alliance, is full of optimism. He believes that as long as there is a market and demand, as the team of host manufacturers grows, the supporting companies will also The level of technology and product supply will keep up accordingly. I hope these can add positive energy to the revitalization of the industrial robot industry.

In many years of practice, based on the examples around us, we specially recommend:

1.Cultivate a qualified talent team

General Secretary Xi stressed: “Empty talk will harm the country, but hard work will make it prosperous.” Over the past five years, in the process of providing supporting and technical services to many domestic industrial robot manufacturers, we have felt that some phenomena are universal. For example, those who are responsible for overall robot design do not seem to be professional enough on how to select and configure bearings, how to select tolerances and fits, how to ensure the accuracy of the main machine, what are the requirements for related accessories, how to inspect and assemble, etc. What’s more, the design is based on imitation of a cat without asking for a thorough understanding; the manufacturing is shoddy and inspection and control are neglected; the assembly is just assembling without matching, and the assembled products are inferior to similar products abroad in terms of precision, flexibility, vibration and noise. There are certain differences in the products. Some companies even bought back foreign robot prototypes, copied them, measured and mapped them, and then assembled them. However, they became “disabled” and could not work normally at all. Although the above situations are not all, they are indeed relatively common.

Reality shows that at all key nodes in China’s robotics field, from design to production and manufacturing, from mainframe to parts, there is indeed a dilemma of lack of qualified talents. At present, in this field, we need not only qualified designers, but also qualified craftsmen and skilled craftsmen. Therefore, while revitalizing key components of robots, it is imperative to create a team of outstanding professional talents.

2.Overcome the tendency to focus on the host and light components

The development of domestic equipment manufacturing industry has long faced the prominent problem of focusing on the main engine and not on components. As my country’s main engine level improves, the bottleneck phenomenon of basic components lagging behind the main engine has become increasingly apparent. As a result, among the 18 major technical equipment key areas supported by the state for development, most of the key basic components of products are dependent on imports and are controlled by others.

What needs to be mentioned in particular here is: when the country begins to pay attention to the development of basic parts and provide relevant policy support, it cannot make the same old mistakes again. The basic parts of basic parts – the bearing and gear industry should also be paid attention to.

At present, in the field of precision reducers, there are mainly two types of reducers used for industrial robots, one is the harmonic reducer, and the other is the RV cycloidal pinwheel reducer. The basic parts of these two reducers are bearings and gears. The high precision and high reliability of the reducer also come from the high precision and high reliability bearings and gears. When revitalizing basic components, they must not be forgotten.

Fortunately, many domestic experts and leaders have noticed this. Many experts pointed out that in the field of key components and general components of high-end intelligent manufacturing equipment, it is necessary to focus on the development of high-performance,high-precision and reliable bearings,hydraulics /Pneumatic/sealing components, gear transmission devices and large precision, complex, long-life molds, etc.

3.Pay attention to international technological development

At present, in high-precision harmonic reducers for robots, the gear transmission adopts double arc tooth profile, which can effectively improve the stress condition of the flexspline tooth root and the transmission meshing quality, improve the load-bearing capacity, torsional stiffness and fatigue life of the flexspline, and Minimum gear ratio can be reduced. In the early 1990s, this technology had been basically perfected, and the international market in this field was mainly monopolized by Japanese companies, while China was just getting started.

Compared with harmonic reducers, RV reducers have higher stiffness and rotation accuracy. The current development direction is how to increase the torsional stiffness and maximum bending moment resistance of the reducer by improving the internal bearing configuration, materials and heat treatment process, and improve its service life under severe working conditions such as frequent acceleration and deceleration. At present, this field is also monopolized by Japanese companies in the international market. In short, China’s industrial robot industry is booming. Accelerating the revitalization of basic parts is of great significance and has a long way to go.

Leave A Comment