Flange bearings are a critical component in a wide range of mechanical systems, from industrial machinery to automotive applications. These specialized bearings play a crucial role in supporting and guiding rotational motion, reducing friction, and ensuring the overall efficiency and reliability of the equipment they are integrated into. This comprehensive guide will explore the different types of flange bearings, their various applications, the advantages they offer, and best practices for installation and maintenance.

Types of Flange Bearings

Ball Bearings

Ball bearings are a type of flange bearing that utilize spherical rolling elements to support radial and axial loads. They are known for their high speed capabilities, low friction, and ability to handle both radial and thrust

Roller Bearings

Roller bearings, on the other hand, employ cylindrical or tapered rolling elements. They are generally better suited for supporting heavier loads and are often used in applications where high radial loads are present, such as in industrial machinery and vehicles.

Sleeve Bearings

Sleeve bearings, also known as plain bearings, do not have rolling elements. Instead, they rely on a sliding motion between the bearing surface and the shaft. These bearings are often more cost-effective and can handle moderate loads, making them a popular choice for less demanding applications.

Applications of Flange Bearings

Automotive Industry

Flange bearings are widely used in the automotive industry, supporting components such as wheels, alternators, and water pumps, ensuring smooth and reliable performance.

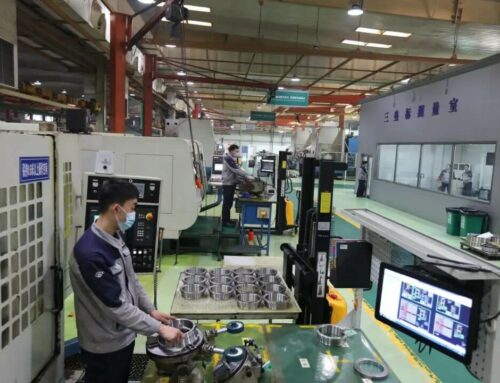

Industrial Machinery

In industrial settings, flange bearings are critical for the operation of equipment like conveyors, fans, and gearboxes, where they help to maintain efficient power transmission and reduce downtime.

Agricultural Equipment

Flange bearings are also essential in agricultural machinery, such as harvesters and irrigation systems, where they must withstand harsh environmental conditions and heavy loads.

Household Appliances

Even in household appliances, such as washing machines and dishwashers, flange bearings play a vital role in ensuring smooth, quiet, and long-lasting operation

Advantages of Flange Bearings

Reduced Friction

Flange bearings are designed to minimize friction, leading to increased energy efficiency and reduced wear and tear on the mechanical components they support.

Heavy Load Support

The flanged design of these bearings allows them to effectively handle and distribute heavy radial and axial loads, making them suitable for demanding applications.

Smooth Rotation

The rolling or sliding motion of flange bearings ensures smooth and consistent rotational movement, enhancing the overall performance and reliability of the machinery.

Versatility

Flange bearings come in a wide range of sizes, materials, and designs, allowing them to be easily integrated into various mechanical systems and applications.

Installing Flange Bearings

Preparation

Thoroughly clean and prepare the mounting surface to ensure proper alignment and fit of the flange bearing. Carefully measure the shaft and housing dimensions to select the appropriate bearing size.

Mounting

Carefully position the flange bearing on the shaft and secure it in place using the appropriate fasteners. Ensure that the bearing is properly aligned and centered to prevent premature wear or failure.

Lubrication

Apply the recommended lubricant to the bearing according to the manufacturer’s specifications. Proper lubrication is crucial for minimizing friction, reducing heat buildup, and extending the bearing’s lifespan.

Maintaining Flange Bearings

Inspection

Regularly inspect the flange bearing for any signs of wear, damage, or contamination. Look for indications of excessive vibration, noise, or temperature changes that could signal the need for maintenance.

Lubrication

Ensure that the bearing is properly lubricated according to the manufacturer’s recommendations. This may involve regular reapplication of grease or oil to maintain the necessary lubrication levels.

Replacement

If the bearing shows signs of significant wear or damage, it should be replaced to prevent further deterioration of the mechanical system and potential failures.

Sincerely hope this post will be kind of useful for you. And if you have any problems during buying flange bearings, please feel free to contact us. Our technician sales will timely get back to you.

Leave A Comment