Motor bearings are very important

As we all know, the motor is one of the important components of the transmission and control system. It can be seen everywhere in our lives, including various household appliances, automobiles, etc.

In industrial production, motors are even more powerful. Various equipment such as steel metallurgy, mining machinery, petrochemicals, and wind power generation all require the application support of high-performance motors.

With the development of modern science and technology, the focus of motors in practical applications has shifted from simple transmission to complex control, especially the precise control of the speed, position and torque of the motor.

As a key component of motor operation, bearings are directly related to the performance and service life of the motor. The manufacturing quality and installation quality of the bearings are key factors to ensure the running quality of the motor.

Motor bearing application areas

Precision motor bearings are mainly used in the fields of industrial general motors (high-efficiency motors), servo motors, special motors, new energy vehicles, and micro/small motors.

In different application fields, ZWZ’s application engineers and process R&D and design experts provide customers with comprehensive solutions based on various complex working conditions and application scenarios.

According to the current market demand trend for motors with special properties such as low noise, low mechanical loss, and high speed, ZWZ has developed PM series bearings for medium and large motors, as well as silent high-speed bearing products for customers.

PM series bearing solutions for medium and large motors

Product technical features:

Optimize raceways and rolling elements

Higher surface machining accuracy

Lower vibration values

Optimized lubrication

New development and design of cage:

Higher stability

Lower noise

More suitable for high speed and impact environments

Optimize sealing solution

Labyrinth non-contact seal

Reduce friction losses

Improve sealing performance

Extend bearing life

Product Range:

Inner diameter; ø70-200mm

Cage: Steel/Copper Alloy

Width series: 200, 300

Cylindrical Roller Bearings:

Inner diameter; ø70-200mm

Cage: Steel/Copper Alloy

Sidewall type: N, NU, NF, NJ

Long life: target operating life of more than 40,000 hours

Low noise: The vibration value adopts internal control standards, and the noise quality reaches Z2/V2 or above.

Low mechanical loss: low friction torque, stable operation, the temperature rise is more than 20% lower than that of general products

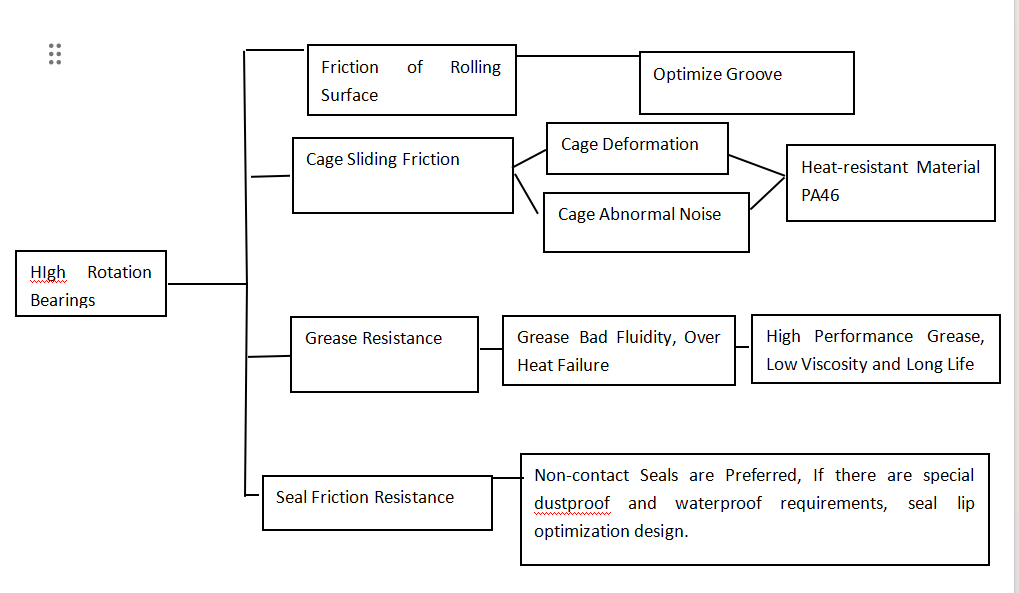

High speed bearing solutions

As the demand for high-efficiency motors increases, the design requirements for high-speed EV drive motors and high-speed servo motors continue to increase, which also puts forward new requirements for various parameters of motor bearings.

When the speed requirements of high-speed motors exceed the limit speed of conventional bearings, it is imperative to develop specially designed bearing products with high DmN values. ZWZ always regards customer needs as the basis of corporate value and survival, and provides customized solutions for high-speed motor customers according to various working conditions.

Leave A Comment