Bearings are widely used in various machinery. It can be said that as long as the machine is running, it is inseparable from bearings. Bearings are also key components of motorcycles.

Because most of the mechanical parts of motorcycles are exposed, they are subjected to the severe test of high-speed rotation in harsh driving environments. This requires motorcycle bearings to meet good durability and high sealing properties to extend the service life of the motorcycle.

Motorcycles vary depending on their model and structure, but each motorcycle is generally equipped with 20 to 30 bearings. These bearings are used in important rotating parts such as engines, transmissions, and wheels that support driving. They are responsible for reducing friction and ensuring that the engine’s power is transmitted to the wheels.

Motorcycle bearing performance

- Smooth rotation with low friction and vibration

- With foreign body resistance and high rigidity

- Durability must be ensured;

Bearings for motorcycle engines and transmissions are required to be resistant to foreign objects and have high rigidity because they are used under conditions of high temperature, high-speed rotation, and heavy impact loads in a foreign object environment. In addition, wheel bearings must be suitable for

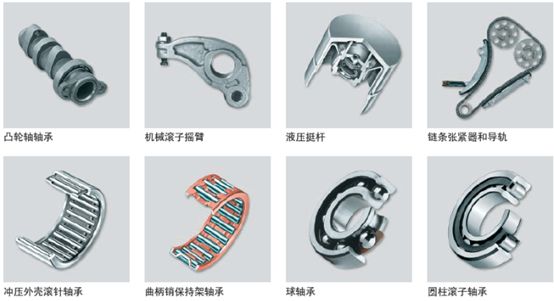

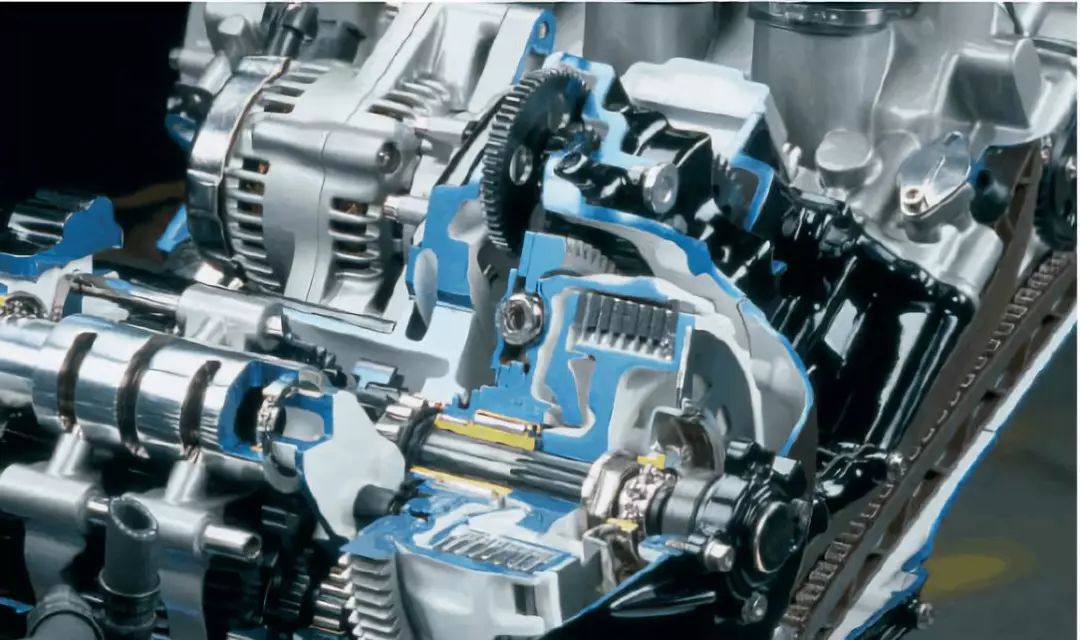

Engine application

Crankshaft

Main bearing: ball bearing, cylindrical roller bearing

Connecting Rod: Crankpin Cage Bearing

Run on time

Camshaft: needle bearings, ball bearings

Auxiliary equipment

Starter: Needle roller bearing

Oil pump: needle bearings, ball bearings

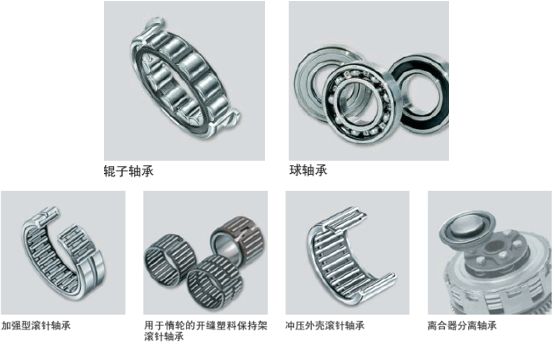

Gearbox application

Drive shaft and transmission shaft

Ball and roller bearings and slotted lightweight plastic cage bearings for idlers

Clutch

Clutch release bearing

Shift gears

Ball bearings, needle roller bearings

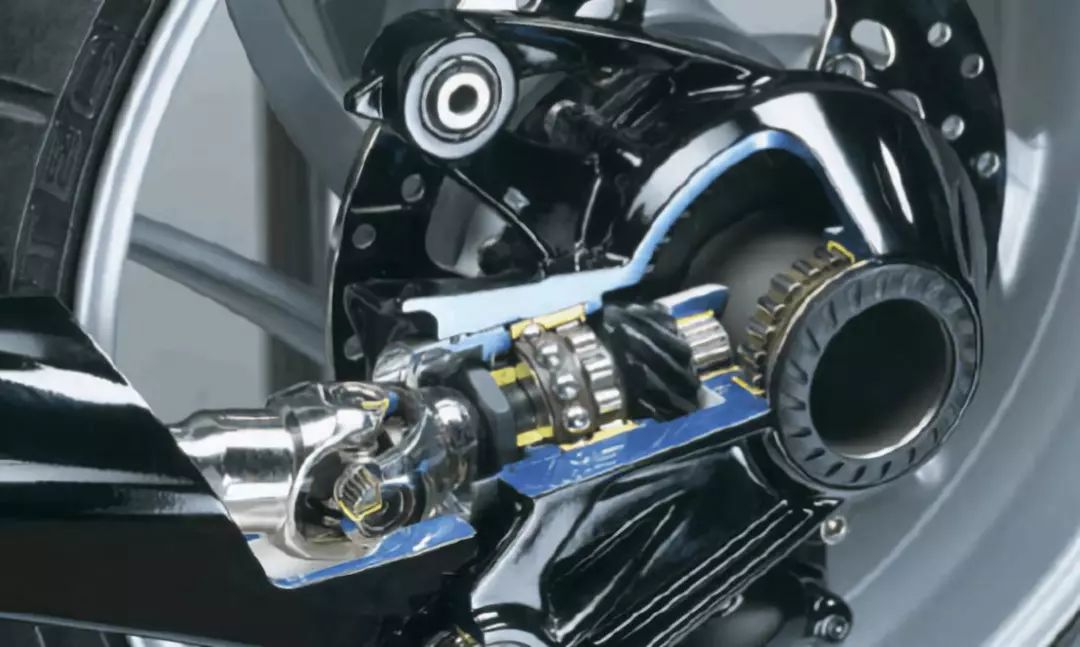

Chassis application

Chassis

Ball bearings, needle roller bearings, tapered roller bearings, angular contact ball bearings, thrust needle roller bearings

Cardan shaft

Cross universal joint

Common models of motorcycle bearings

On motorcycles, ball bearings are generally used in the engine’s internal transmission system and wheels, plane ball bearings are used in the front fork, and needle roller bearings are used in the crankshaft connecting rod and some transmission gear shafts.

Generally speaking, the front wheels of cars below 100cc are 6200, 6201, 6300, 6301 and the rear wheels are 6301

The front wheels of 125cc and 150cc cars are 6301 and the rear wheels are 6202, 6302, 6200, 6201, 6202, 6203, 6204, 6205, 6206, 6300, 6301, 6302, 6000, 6001, 6002, 6003, 6004, 62/22 ,62/28,62/32,63/22,63/28,63/32

Causes and analysis of early damage

- Bearings on the front and rear wheel hubs and the rear chain plate

- Because owners wade into too deep water or wash their cars frequently during daily use, water enters the bearings, causing the grease in the bearings to gradually fail, resulting in serious wear of the rolling grooves and balls in the bearings, and a significant increase in clearance;

- Suppose the front and rear wheels are too tight or too loose when leaving the factory or being sold. In that case, it will cause unstable driving over time, bearing jamming or loose bearing displacement, and the ball cage will be damaged or fall off, resulting in an excessive gap, causing the brake disc to be in contact with the wheel hub. Friction increases the resistance of driving;

- The bearings on the rear sprocket are prone to water intrusion or are adjusted too tight or too loose, which can cause damage. Therefore, owners should pay special attention when washing the car or entering deep puddles, and perform timely inspection and maintenance. If it is damaged, the replacement must be in place and adjusted until the wheel rotates flexibly and there is no obvious clearance.

- Crankshaft connecting rod big and small head roller bearings and ball bearings on both sides

- Generally, two-stroke engines are more susceptible to damage. The main cause of damage to the connecting rod’s large and small roller bearings is: the engine oil quality is too poor or the oil volume is too small.

- When the engine is working, the temperature is too high, intensifying the frictional heat generation and softening the surface, causing premature fatigue spalling on the working surface. The peeled-off particles enter the cage of the steel cage, causing operation blockage; the rollers generate abnormal loads on the cage, aggravating the wear of the cage causing the cage to break and the crankshaft connecting rod to lock.

- Bearings on the rear wheels of the chartered car

- Generally, the shock absorption of a chartered motorcycle is a single support with a large load capacity. If the motorcycle does not slow down in bad road conditions, it will easily cause wear and tear and affect the service life. When washing the motorcycle, you should pay attention to the fact that water can easily enter.

- Steering column upper and lower bearings

- Due to the failure of the front shock absorber, insufficient lubrication, or improper tightening of the upper and lower parts, the balls are broken or the ball working surface is peeled off, causing the steering wheel to become stiff or deviated, affecting the safety of driving.

To sum up: Bearing damage is mainly caused by factors such as poor lubrication, improper installation, improper clearance and harsh operating environment. If not discovered or repaired early, it will cause greater losses or affect driving safety. Therefore, manufacturers, dealers, maintenance industries and car owners are requested to pay attention to avoid such accidents.

Leave A Comment